| Backlink to the CGSE Documentation Website | |

|---|---|

Commanding Manual (this document) |

|

Changelog

- 29/03/2024 — 0.13

-

-

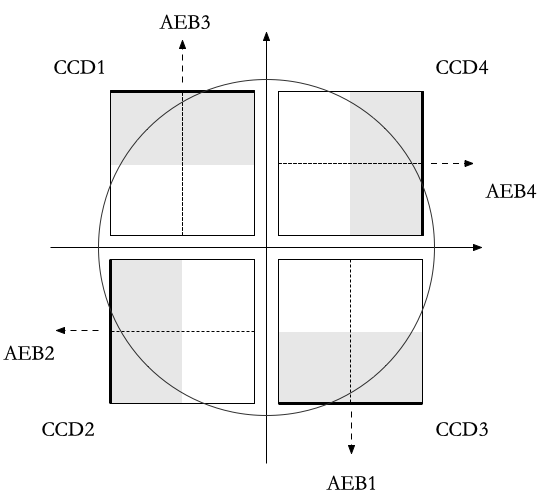

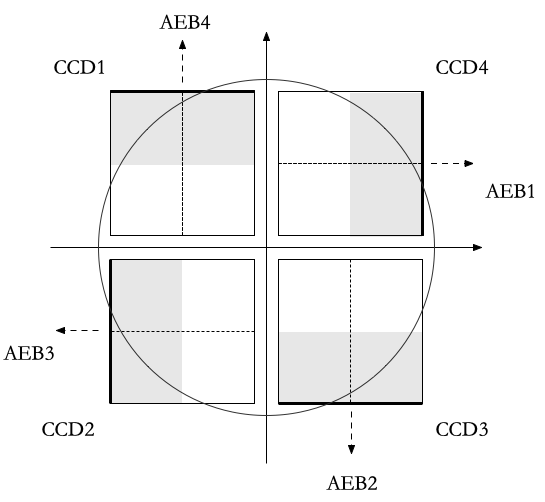

Added proper figures for the F-CAM CCD and AEB numbering, see Section 13.4.1.

-

- 18/03/2024 — 0.12

-

-

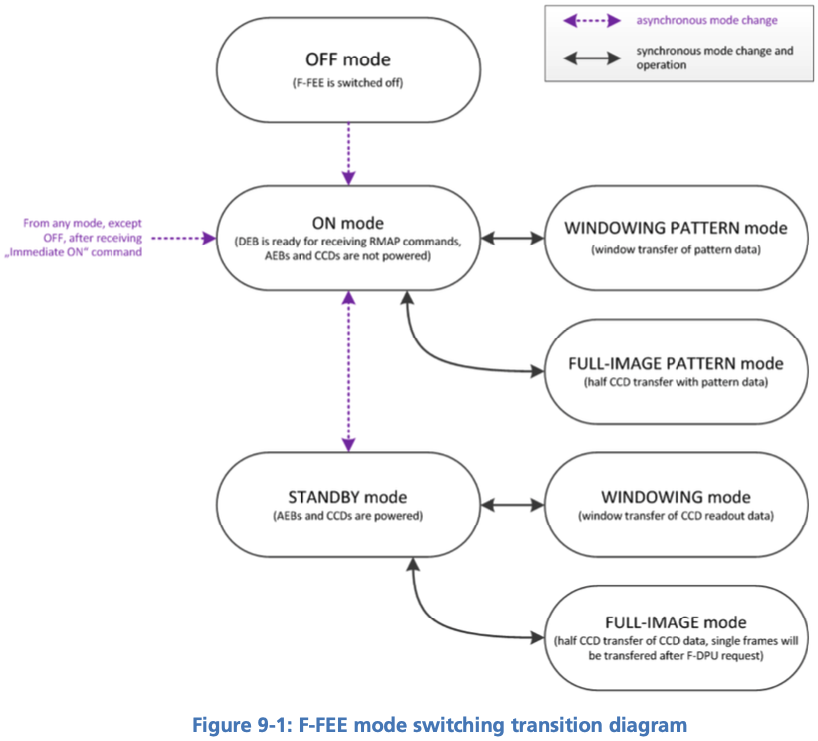

Added a section on F-FEE operation (by Pierre Royer), see Chapter 13.

-

- 12/02/2024 — 0.11

-

-

Added a warning that loading/submitting a Setup doesn’t propagate this new Setup to all components in the system, see Chapter 6

-

- 29/06/2023 — 0.10

-

-

Added table with N-FEE modes and their register values for PFM, see Table 3

-

- 28/06/2023 — 0.9

-

-

Added an appendix to explain the difference between GitHub issues, NCRs and PVS, see Appendix 18.E

-

Added a section on actions on the Setup when a new camera arrives, see Chapter 9. (This is taken from a technical note by Pierre PLATO-KUL-PL-TN-0022)

-

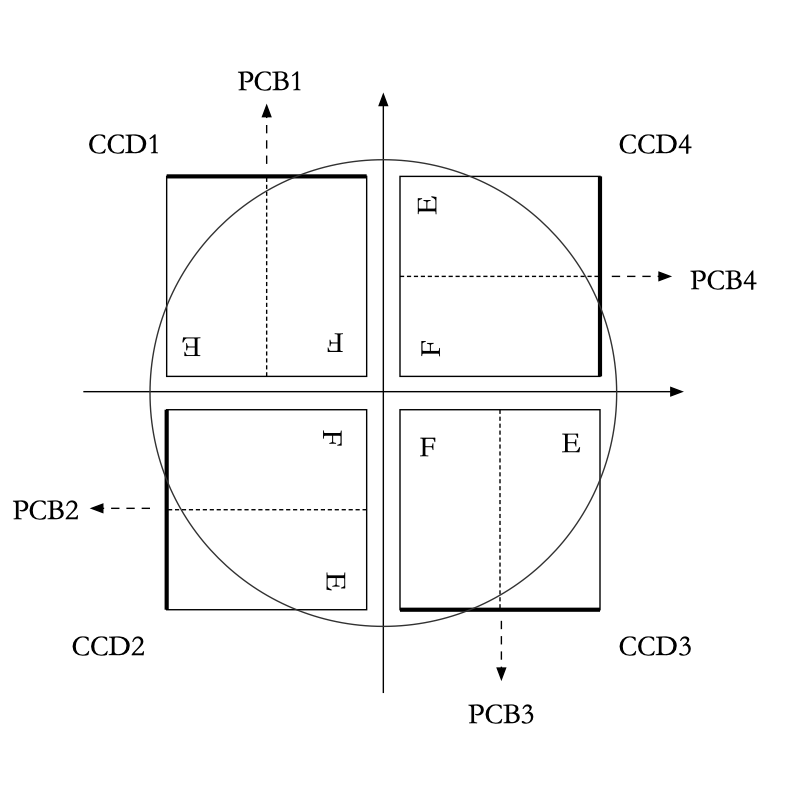

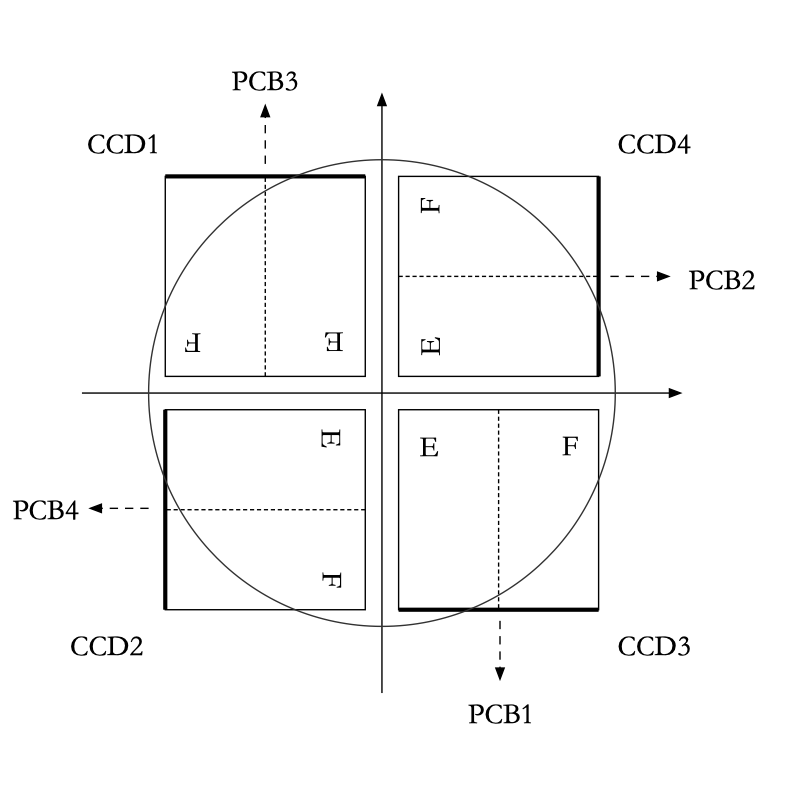

updated CCD layout images in a TAB for EM and FM, see Chapter 12.

-

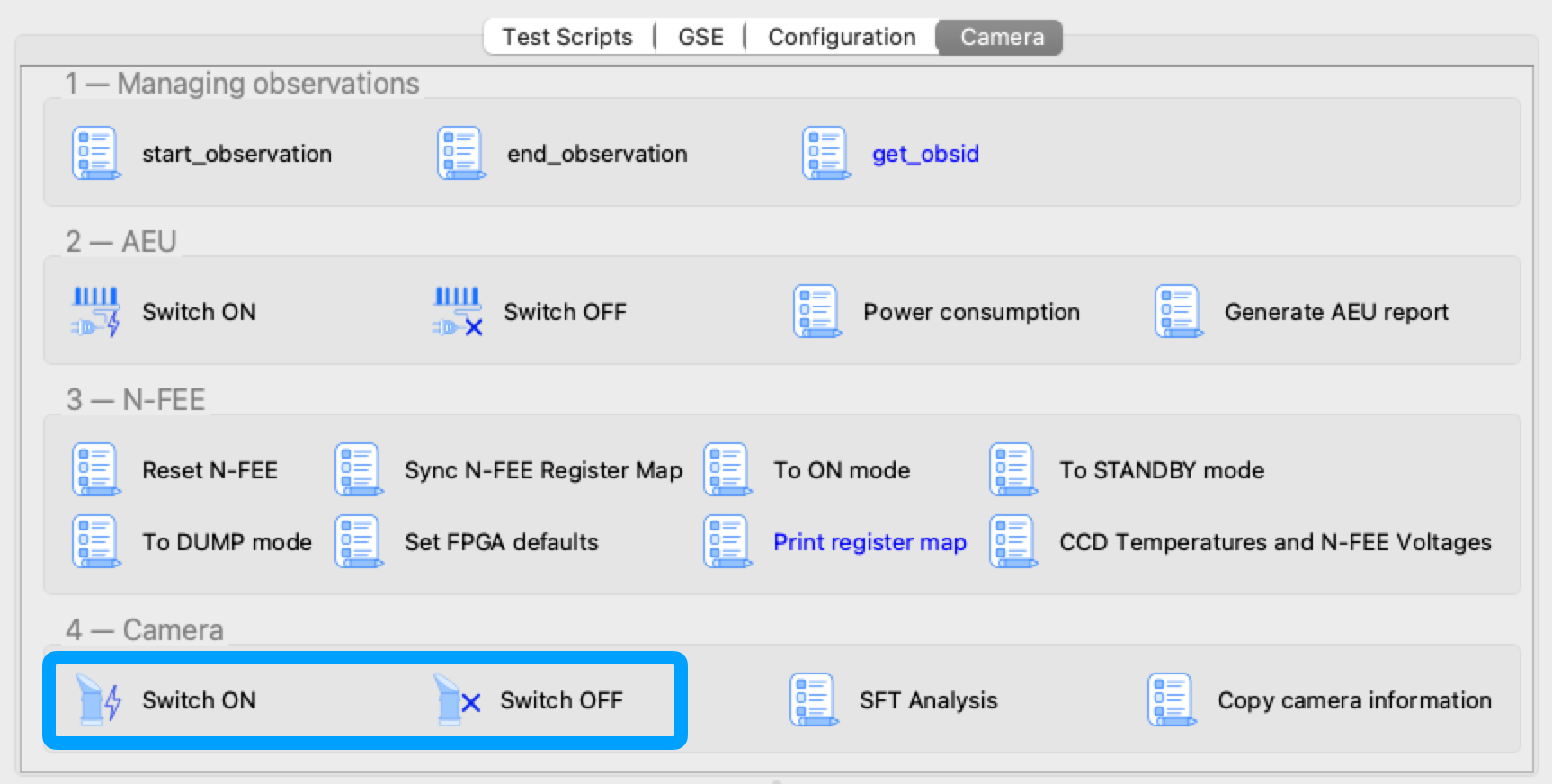

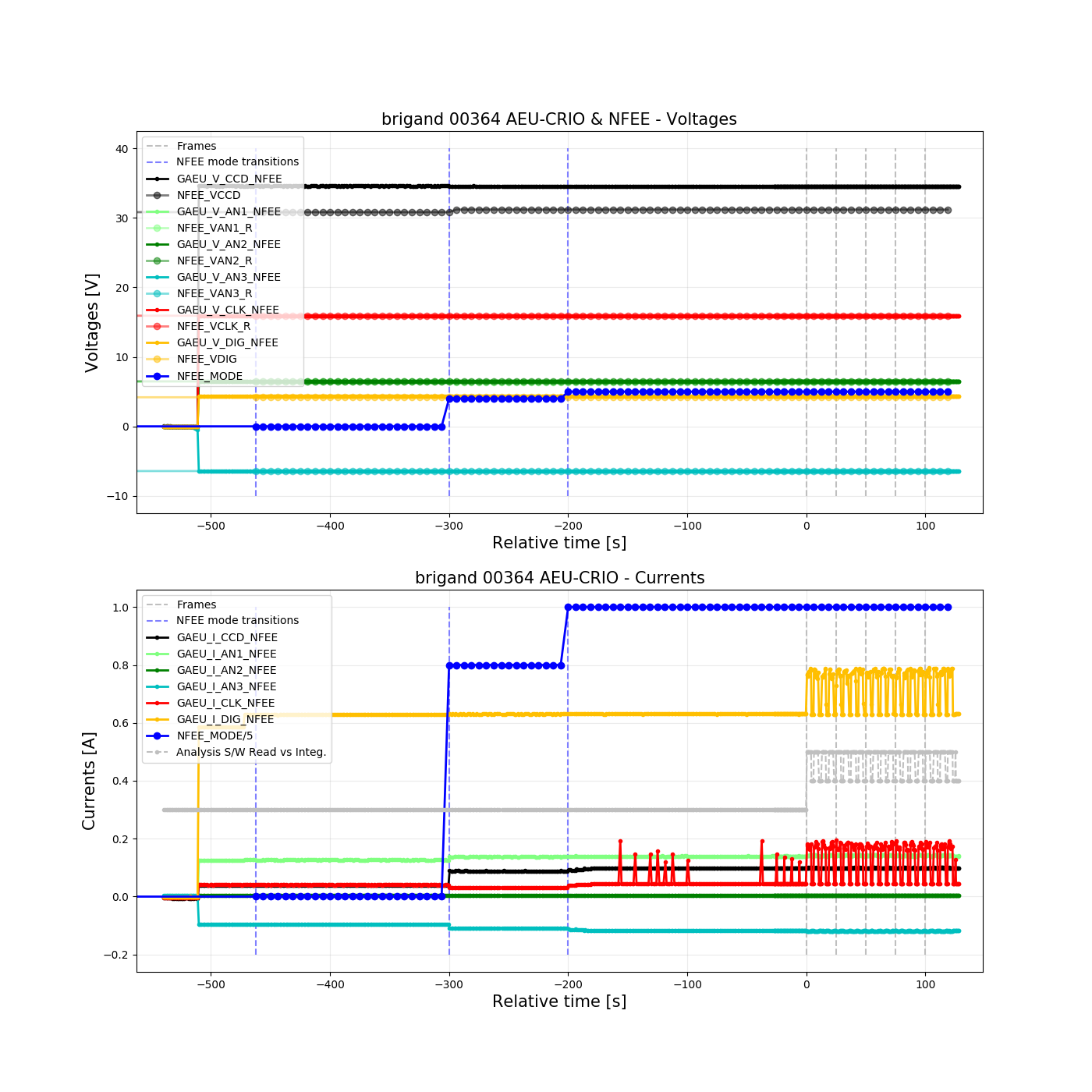

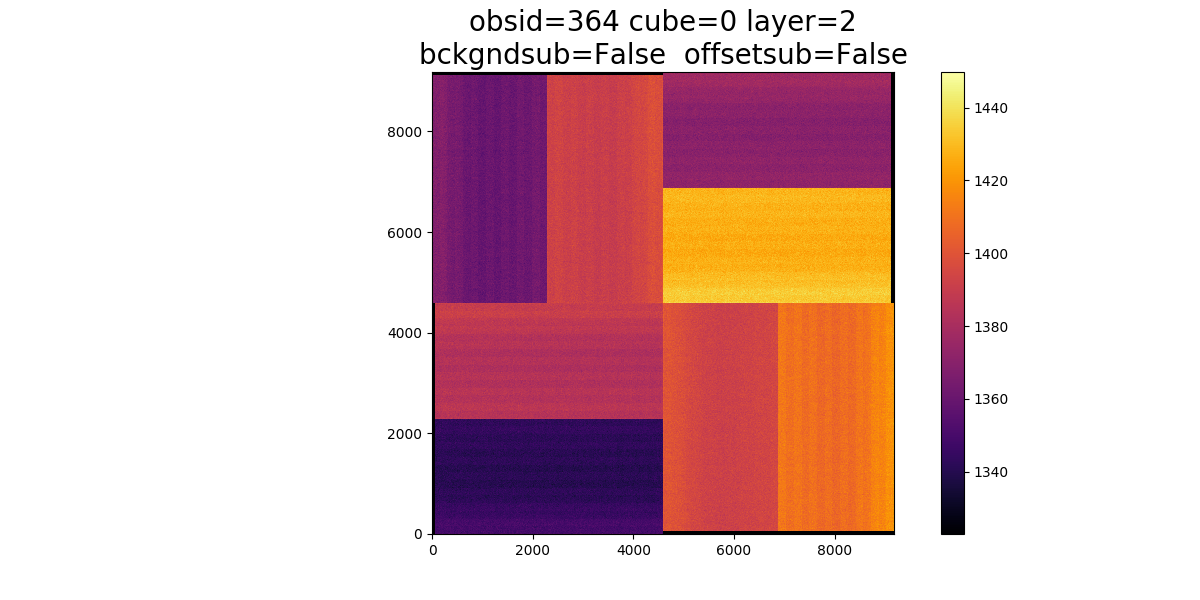

Added section on SFT analysis to section on Camera Switch ON, see Chapter 10.

-

minor editorial changes like fixing links, typos, minor rewording, etc.

-

- 20/06/2023 — v0.8

-

-

Added explanation about Camera Switch ON / OFF, see Chapter 10

-

- 19/06/2023 — v0.7

-

-

bringing the commanding manual up-to-date with the current implementation of the Common-EGSE, the test scripts and the situation in the test houses.

-

Section on the plato-test-prep repository has been removed (was Section 3.3)

-

Data Acquisition: updates in all sections

-

Configuration and Setups: updates in all sections

-

Common-EGSE startup, shutdown and sleep: updates in all sections

-

Utility functions: updates in all sections

-

Operating the N-FEE: updates in all sections

-

Operating the TCS EGSE: only editorial updates

-

Operating the OGSE: updates in all sections

-

Operating the tests, system states: only editorial changes

-

Appendix A: removed unimplemented ALT mode for

ccd_sideand updated other commands with correct parameters -

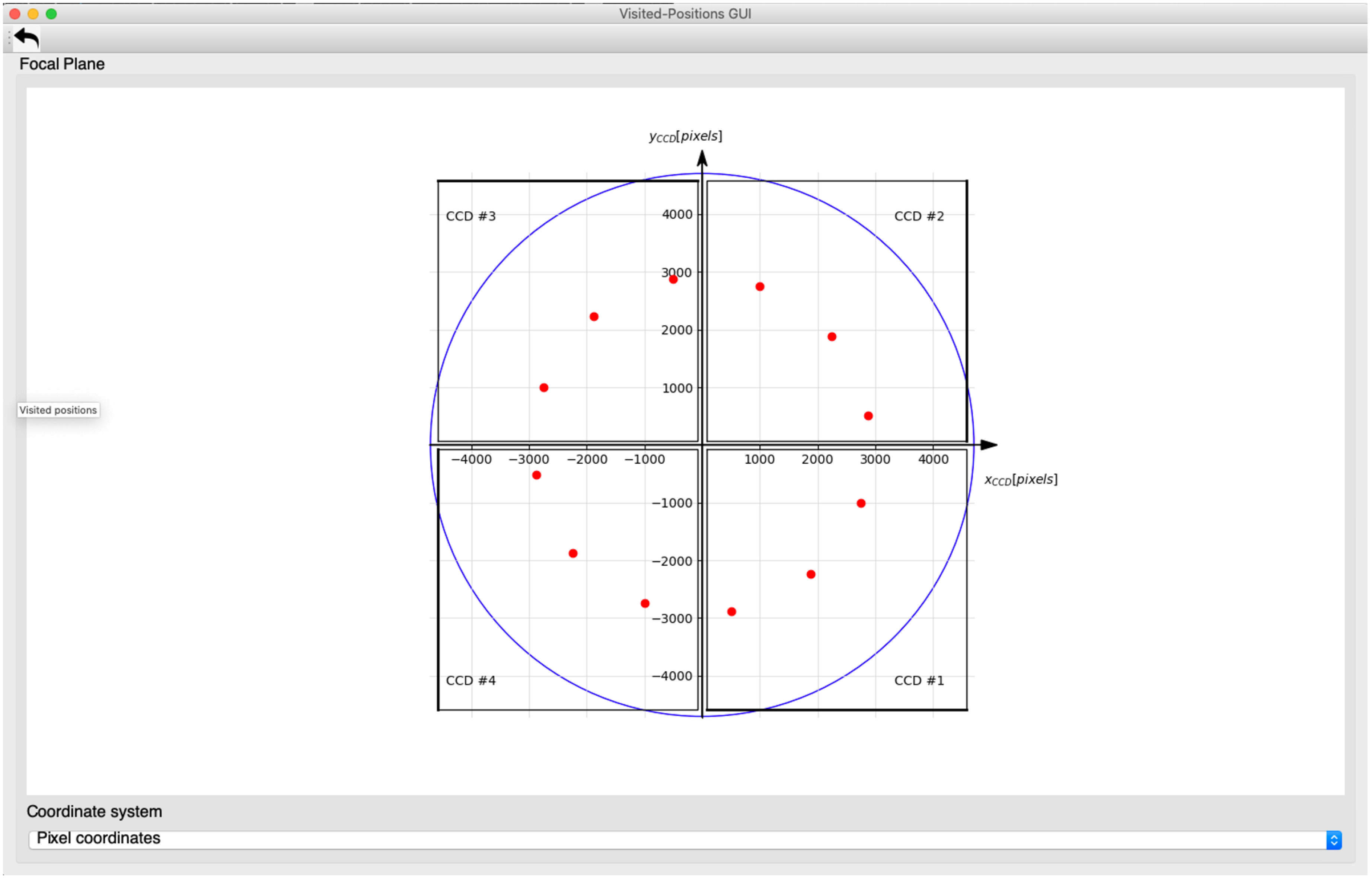

Appendix B: updated commands for visited positions

-

-

added a backlink to the CGSE Documentation web site for your convenience. It’s at the top of the HTML page.

-

Click to see older changelog entries

- 12/06/2023 — v0.6

-

-

move the commanding manual to the CGSE documentation page and converted into asciidoc.

-

Update section on data structure

-

- 14/06/2021 — v0.5

-

-

Update section 11.3 (rem. col_end from BB signatures)

-

- 03/05/2021 — v0.4

-

-

Update sections 3.2, 3.3, 7.3, 7.4

-

Sections 11.1 & 11.3 Change ccd_side & EF convention

-

New sections 5.3, 6.3, 11.4 and 14

-

Update sections 3.2, 3.3, 7.3, 7.4

-

Sections 11.1 & 11.3 Change ccd_side & EF convention

-

New sections 5.3, 6.3, 11.4 and 14

-

Colophon

Copyright © 2022, 2023 by the KU Leuven PLATO CGSE Team

1st Edition — February 2023

This manual is written in PyCharm using the AsciiDoc plugin. The PDF Book version is processed with asciidoctor-pdf.

The manual is available as HTML from ivs-kuleuven/github.io. The HTML pages are generated with Hugo which is an OSS static web-pages generator. From this site, you can also download the PDF books.

The source code is available in a GitHub repository at ivs-kuleuven/plato-cgse-doc.

When you find an error or inconsistency or you have some improvements to the text, feel free to raise an issue or create a pull request. Any contribution is greatly appreciated and will be mentioned in the acknowledgement section.

Conventions used in this Book

We try to be consistent with the following typographical conventions:

- Italic

-

Indicates a new term or …

- Constant width

-

Used for code listings, as well as within paragraphs to refer to program elements like variable and function names, data type, environment variables (

ALL_CAPS), statements and keywords. - Constant width between angle brackets

<text> -

Indicates

textthat should be replaced with user-supplied values or by values determined by context. The brackets should thereby be omitted.

When you see a $ … in code listings, this is a command you need to execute in a terminal (omitting the dollar sign itself). When you see >>> … in code listings, that is a Python expression that you need to execute in a Python REPL (here omitting the three brackets).

- Setup versus setup

-

I make a distinction between Setup (with a capital S) and setup (with a small s). The Setup is used when I talk about the object as defined in a Python environment, i.e. the entity itself that contains all the definitions, configuration and calibration parameters of the equipment that make up the complete test setup (notice the small letter 's' here).

(sometimes you may find setup in the document which really should be 'set up' with a space)

- Using TABs

-

Some of the manuals use TABs in their HTML version. Below, you can find an example of tabbed information. You can select between FM and EM info and you should see the text change with the TAB.

| This feature is only available in the HTML version of the documents. If you are looking at the PDF version of the document, the TABs are shown in a frame where all TABs are presented successively. |

-

FM

-

EM

In this TAB we present FM specific information.

In this TAB we present EM specific information.

- Using Collapse

-

Sometimes, information we need to display is too long and will make the document hard to read. This happens mostly with listings or terminal output and we will make that information collapsible. By default, the info will be collapsed, press the small triangle before the title (or the title itself) to expand it.

| In the PDF document, all collapsible sections will be expanded. |

A collapsible listing

plato-data@strawberry:/data/CSL1/obs/01151_CSL1_chimay$ ls -l total 815628 -rw-r--r-- 1 plato-data plato-data 7961 Jun 20 10:38 01151_CSL1_chimay_AEU-AWG1_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 9306 Jun 20 10:38 01151_CSL1_chimay_AEU-AWG2_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 309375 Jun 20 10:38 01151_CSL1_chimay_AEU-CRIO_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 42950 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU1_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 43239 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU2_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 42175 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU3_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 42327 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU4_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 42242 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU5_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 42269 Jun 20 10:38 01151_CSL1_chimay_AEU-PSU6_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 67149 Jun 20 10:38 01151_CSL1_chimay_CM_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 20051 Jun 20 10:38 01151_CSL1_chimay_DAQ6510_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 105 Jun 20 10:38 01151_CSL1_chimay_DAS-DAQ6510_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 19721 Jun 20 10:38 01151_CSL1_chimay_DPU_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 22833 Jun 20 10:38 01151_CSL1_chimay_FOV_20230620_095819.csv -rw-rw-r-- 1 plato-data plato-data 833754240 Jun 20 10:34 01151_CSL1_chimay_N-FEE_CCD_00001_20230620_cube.fits -rw-r--r-- 1 plato-data plato-data 292859 Jun 20 10:38 01151_CSL1_chimay_N-FEE-HK_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 8877 Jun 20 10:38 01151_CSL1_chimay_OGSE_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 19841 Jun 20 10:38 01151_CSL1_chimay_PM_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 188419 Jun 20 10:38 01151_CSL1_chimay_PUNA_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 7662 Jun 20 10:38 01151_CSL1_chimay_SMC9300_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 19781 Jun 20 10:38 01151_CSL1_chimay_SYN_20230620_095819.csv -rw-r--r-- 1 plato-data plato-data 147569 Jun 20 10:38 01151_CSL1_chimay_SYN-HK_20230620_095819.csv plato-data@strawberry:/data/CSL1/obs/01151_CSL1_chimay$

Purpose

This document describes the concepts and some practicalities relative to the commanding of the PLATO Cameras (AEU, FEE) and various GSEs to be controlled during the ground-based testing of the PLATO Cameras.

The document shall be used to train members of the PLATO camera test team in operating the Common-EGSE system and write commanding scripts for camera-level tests.

The present version still contains a few ‘TBW’, some of which will be filled thanks to inputs from the Test Houses (TH), describing the location-specific GSE controls.

Documents and Acronyms

Applicable documents

| ID | Document Title | Document Number | Issue |

|---|---|---|---|

Reference Documents

| ID | Document Title | Document Number | Issue |

|---|---|---|---|

RD-01 |

CAM Test EGSE User Manual |

PT-EVO-SYS-MA-0261-1 |

1 |

RD-02 |

Common-EGSE User Manual |

PLATO-KUL-PL-MAN-0001 |

0.1 |

RD-03 |

Test Specification |

PLATO-KUL-PL-TS-0001 |

2.7 |

RD-04 |

Common-EGSE ICD |

PLATO-KUL-PL-ICD-0002 |

1.0 |

RD-05 |

PLATO-AEU CAM TEST EGSE TMTC ICD |

PTO-ECO-SYS-ICD-0188 |

2B |

RD-06 |

PLATO N-FEE ICD |

PLATO-MSSL-PL-ICD-0002 |

9.0 |

RD-07 |

Reverse clocking for N-CAMs |

PLATO-MSSL-PL-TN-0015 |

1.0 |

RD-08 |

N-FEE Readout Operations |

PLATO-MSSL-PL-TN-0012 |

2.1 |

RD-09 |

PLATO PL TCGSE UNIT Subsystems and Equipment ICD and IDS |

PTO-AST-PL-TCGSE-ICD-0012 |

10.0 |

RD-10 |

PLATO Instrument Coordinate Systems |

PLATO-OHB-PL-LI-0009 |

05 |

RD-11 |

PLATO Room temperature collimator user manual |

PLATO-UOL-PL-RP-0004 |

1 |

RD-12 |

R1_CalibrationReport |

PLATO-PL-CSL-RP-0031 |

3.0 |

RD-13 |

R2_CalibrationReport |

PLATO-PL-CSL-RP-0032 |

2.1 |

RD-14 |

N-FEE Conceptualised Operation Specification |

PLATO-MSSL-PL-SP-0015 |

2.0 |

RD-15 |

PLATO N-FEE PFM Register Map |

PLATO-MSSL-PL-FI-0004 |

1.0 |

RD-16 |

PLATO F-FEE CD ICD |

PLATO-DLR-PL-ICD-0007 |

2.6 |

Acronyms

AEU |

Ancillary Electronics Unit |

API |

Application Programming Interface |

CAM |

Camera |

CCD |

Charged-Coupled Device |

CGSE |

Common-EGSE |

CSL |

Centre Spatial de Liège |

CSV |

Comma-Separated Values |

COT |

Commercial off-the-shelf |

CTI |

Charge Transfer Inefficiency |

CTS |

Consent to Ship |

DPU |

Data Processing Unit |

DSI |

Diagnostic SpaceWire Interface |

EGSE |

Electrical Ground Support Equipment |

EOL |

End Of Life |

FAQ |

Frequently Asked Questions |

FEE |

Front End Electronics |

FITS |

Flexible Image Transport System |

FPA |

Focal Plane Assembly/Array |

GSE |

Ground Support Equipment |

GUI |

Graphical User Interface |

HDF5 |

Hierarchical Data Format version 5 (File format) |

HK |

Housekeeping |

IAS |

Institut d’Astrophysique Spatiale |

ICD |

Interface Control Document |

LDO |

Leonardo space, Italy |

MGSE |

Mechanical Ground Support Equipment |

MMI |

Man-Machine Interface |

NCR |

Non-Conformance Report |

NRB |

Non-Conformance Review Board |

OBSID |

Observation Identifier |

OGSE |

Optical Ground Support Equipment |

OS |

Operating System |

Portable Document Format |

|

PID |

Process Identifier |

PLATO |

PLAnetary Transits and Oscillations of stars |

PPID |

Parent Process Identifier |

PLM |

Payload Module |

PVS |

Procedure Variation Sheet |

REPL |

Read-Evaluate-Print Loop, e.g. the Python interpreter prompt |

RMAP |

Remote Memory Access Protocol |

SFT |

Short Functional Test |

SpW |

SpaceWire |

SQL |

Structured Query Language |

SRON |

Stichting Ruimte-Onderzoek Nederland |

SUT |

System Under Test |

SVM |

Service Module |

TBC |

To Be Confirmed |

TBD |

To Be Decided or To Be Defined |

TBW |

To Be Written |

TC |

Telecommand |

TCS |

Thermal Control System |

TH |

Test House |

TM |

Telemetry |

TOU |

Telescope Optical Unit |

TS |

Test Scripts |

TUI |

Text-based User Interface |

TV |

Thermal Vacuum |

UM |

User Manual |

USB |

Universal Serial Bus |

YAML |

YAML Ain’t Markup Language |

1. Introduction

1.1. Contents

This document describes the usage of the PLATO Common-EGSE to command the PLATO camera (SUT) and the ground support equipment (GSE) during the PLATO camera ground testing.

Throughout this document, we use the following notation:

-

a command to be executed in a terminal on either the egse-server or on the client machine.

$ command

-

a command to be executed in a Python session. This Python session will always be running on the client machine.

>>> command

1.2. EGSE commanding software environment

The user interface to the PLATO camera EGSE is a software application developed at KU Leuven in collaboration with the test houses for site specific components. It provides graphical user interfaces to control the software processes in the system, monitor telemetry parameters, provide the operator with quick-look analysis images of the camera detectors, etc. It also features a commanding interface in Python. The commanding logic is entirely defined in Python. The hardware interfaces have been implemented in Python (possibly accessing a library written in the C programming language), and the user is accessing these by executing higher-level Python functions in a Python interpreter.

1.3. How different user profiles use the software

-

test-operator: running a test, launching scripts and inspecting results of quick look analysis script at the test house. The test operator is knowledgeable of the Common-EGSE, Test Scripts, all GSE and basic operation of the PLATO Camera (SUT).

-

test-developer: translating test specification into commanding scripts, writing quick-look analysis scripts.

-

offline-analyst: loads the test data from the archive and process this data for validation and feedback.

-

site-operator: manages the test-infrastructure, i.e. the test-environment in the TH, administration of egse-server and client machines.

-

site-developer: implements test house specific software for test equipment used at test houses. This includes but is not limited to device drivers, GUI applications, local setups.

Typical flow of events and responsibilities:

-

Long before the tests are executed, the site-developer implements the interfaces to the test-equipment in the Common-EGSE.

-

Months before the test, the test-developer turns the test-specification into a commanding script.

-

Minutes before the test, the site-operator starts up the system, activates all connections, launches GUIs, loads the proper system configuration into the system, and gives a go-ahead to the test-operator.

-

At t0, the test-operator launches the execution of the commanding script and follows it in real-time.

-

At the end of the execution, the analyst gets hold of the data and starts the analysis.

This commanding manual is mainly targeted at the test developers, the test operators and the analysts. The site-operators and site-developers will find most of the information they need in the Common-EGSE installation manual and user manual.

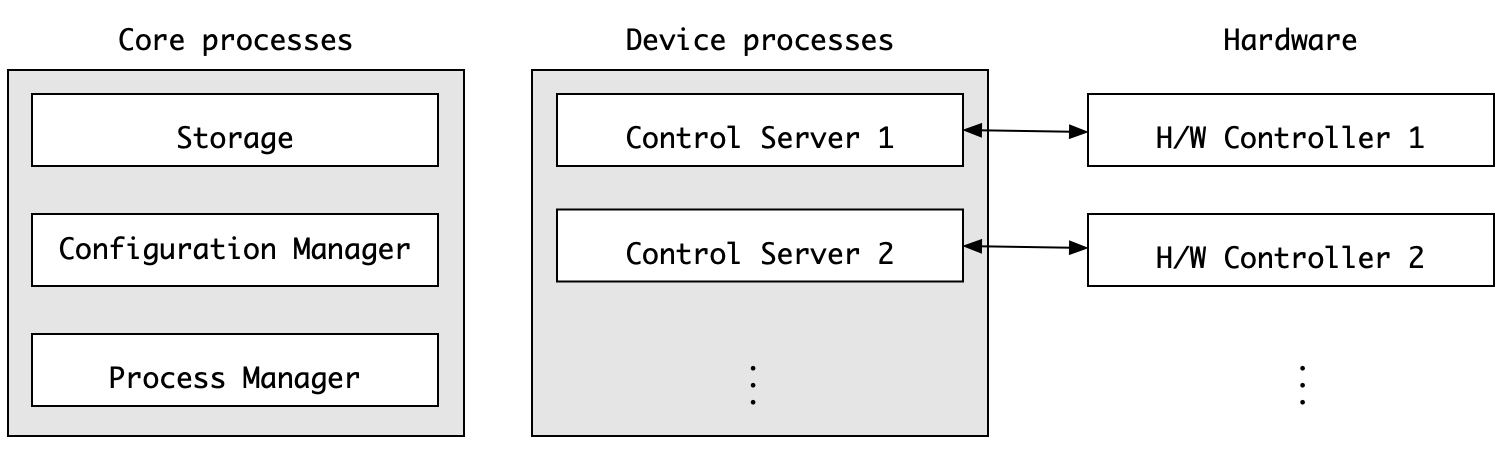

2. Software Overview

The PLATO commanding during ground-based testing resides upon three GitHub repositories:

Amongst others, the documentation will point you to the installation guides, list the low-level commands that are available in the Common-EGSE, list the low-level building blocks implemented in the test scripts etc.

2.1. The plato-common-egse GitHub repository

This repository contains the background infrastructure to interface with the actual hardware in the test housess. The complete documentation can be found in the link above, and in RD-02, see Reference Documents.

In a nutshell, it provides access to all the necessary functions to

-

Operate the camera under test

-

Operate all devices in the test-environment (in or out of the TVAC chamber)

-

Record all telemetry

-

From the camera (image data & HK)

-

From the test-environment (HK)

-

-

Maintain the setup and calibration file information under configuration control (see ‘setup’ below).

-

Command the camera and the test-environment devices from Python scripts (see plato-test-scripts)

The THs are expected to contribute to this repository, to implement the interfaces to their own environment and devices, so they should fork this repository in order to be able to create pull requests.

The test-operators are not expected to contribute to this repository, so they should clone the repository.

2.2. The plato-test-scripts GitHub repository

This repository contains the Python scripts

-

for commanding the tests as defined in the test specification,

-

for analysing the data

The commanders and the THs are expected to contribute to this repository, so everyone should fork it.

2.3. The plato-cgse-conf GitHub repo

This repository holds the setups saved during the tests under configuration control. The concept of setup is explained in Chapter 6.

No one is expected to contribute directly to this repository as it is maintained by the Common-EGSE. The repository can be cloned for inspection.

2.4. Software installation

Operators use the software installation at the test house on the operational machine. The installation is read only and under configuration control. Only official releases shall be installed on the operational machines. The installation is maintained by the site-operator. Please refer to the on-line documentation of the Common-EGSE for full installation details.

$ git clone https://github.com/IvS-KULeuven/plato-common-egse.git $ git checkout tags/<release-tag> -b <release-tag>-branch $ python3.8 setup.py install --home=/cgse

The test-developer uses an installation that is more suited for development of scripts and can be changed. The test-developer has forked the repo on the GitHub website to her personal GitHub account and clones the repo from that account. She works in a virtual environment. Please refer to the Common-EGSE on-line docs for full details.

$ git clone https://github.com/<github-username>/plato-common-egse.git $ source venv/bin/activate $ python3.8 setup.py develop

Please note that the installation examples above are simplified and serve as a reminder. The full installation process is detailed in the on-line Common-EGSE documentation.

2.5. Naming Convention

The table below summarises the coding style that we have adopted for this project. More detailed information can be found in the on-line documentation at github.io: Development notions: Style Guide

| Type | Style | Examples |

|---|---|---|

Variables, building_block parameters, Entries in setup files |

lowercase with underscores |

key, last_value, model, index, user_info |

Methods, functions, building_blocks |

lowercase with underscores |

get_value, set_mask, create_image |

Classes |

CapWords (no underscores) |

ProcessManager, ImageViewer, CommandList, Observation, MetaData |

Constants |

UPPERCASE with underscores |

MAX_LINES, BLACK, COMMANDING_PORT |

Modules & Packages |

lowercase without underscores |

dataset, commanding, multiprocessing |

- Top-level scripts

-

Top-level scripts start with the test identifier from the test specification, followed by a descriptive name in lowercase, words separated by underscores, e.g.,

cam_tvpt_010_best_focus_determination.py. - Building blocks

-

Building blocks are normal function definitions that are decorated with @building_block to identify them as separated by one underscore, i.e., snake_case.

- User utility functions

-

User functions are normal Python functions and follow normal Python function naming conventions, i.e., all lower case and words separated by underscores, i.e., snake_case.

3. Test script architecture

3.1. Overview

At the user level, the PLATO commanding resides upon a few key concepts

-

Building-block: a building block is a Python function implementing the commands corresponding to a logical entity within a test (a Lego©-bloc) or an entire test (the Lego©-house, called “test-script”).

-

Test-script: a test-script is a building block encapsulating all the commands necessary for a given test. The name of a test-script should identify it in the test-specification document (RD-03). The test-script should be unique, i.e. the test script for any given test should be useable in all test-houses.

-

Execution: building blocks, and only building blocks, can be executed, i.e. run on the operational machine inside the test-environment.

-

Observation: executing a building block triggers the creation of an “observation”. An observation is defined by a unique “observation identifier” (obsid) and lasts as long as the execution of the corresponding test (building block).

-

Setup: a Setup encapsulates the complete configuration of the test-environment (test-equipment) and of the camera (test-item) as well as all calibration files associated either to the hardware, or necessary for a given test.

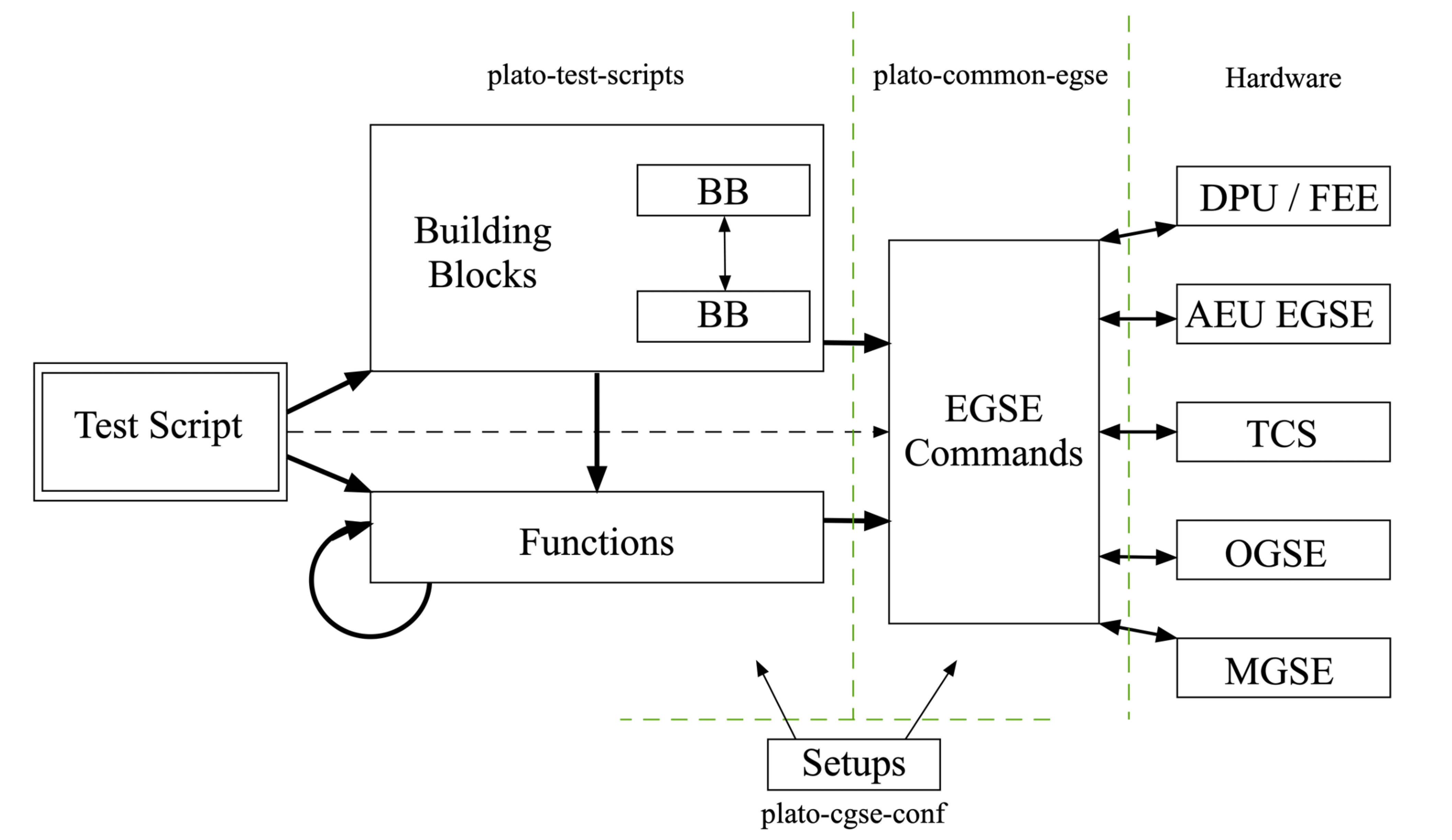

More information on some of these elements are given in the next sections. The figure below describes the generic software architecture in place for the PLATO commanding:

-

At the top level

-

a test script implements an entire test.

-

-

At an intermediate level

-

The test script can call Python functions (e.g. “calculate the next FOV position to visit”) or lower level building blocks (e.g. “go to the next FOV position” or “acquire images over a 5x5 dither pattern”)

-

Building blocks can call other building blocks, or regular Python functions (recursion is forbidden within building blocks)

-

Functions can call other functions, but should not call building blocks

-

-

At the lowest level, the Common-EGSE software provides all the “atomic commands” necessary to interface with the hardware. This layer allows to provide the users with user-friendly commands (e.g. human-readable parameter names, and no bit-field or hexadecimal numbers to provide).

-

The active test-setup is available at all levels to provide all necessary information with respect to hardware or calibration.

3.2. Building block

3.2.1. Definition of a building block

A building block is a Python function marked with a specific decorator in the code. That simply means that the line directly above the definition of the building block in the code should be @building_block:

Example of a building block definition:

@building_block

def move_filter_wheel(position=None):

# your code comes here

return TrueAll parameters of a building block are keyword parameters. That means the parameter name and its value must be specified when calling the building block.

...

move_filter_wheel(position="A")

...3.2.2. Building block justification

Execution: Building blocks are the only entity in the code that will be accepted for execution on the operational machines in the test-environments (THs).

Structure: a unique identifier (BBID) is automatically attributed to every building block entering the plato-test-scripts repository. At every moment during a test execution, the current BBID is recorded in the data (TBC).

Organising a test script into a logical structure and implementing the underlying building blocks accordingly will help structure the data, which in turn will be precious to ease the analysis.

For instance, if a test-script (BB1) is calling building blocks BB2 and BB3 sequentially, the telemetry will contain a sequence of timestamps where the individual building-blocks start, or end.

Note that, as a further convenience, a building block counter (BBCOUNT) will also be recorded, which is a natural number incremented by one every time the active BBID is changing, hence running from 0 to 4 in the example above (TBC).

3.2.3. The properties of a building block

Building blocks implement some safeguards, imposing a number of limitations on the code

-

Building blocks cannot be called recursively. Beware of building blocks calling other building blocks. Avoid too many layers. Avoid functions calling building blocks

-

At run time, the names and the values of every arguments of a building blocks must be explicitly given. Building blocks with many parameters are hence strongly discouraged

-

def my_block(param1, param2=3): is forbidden for 2 reasons-

Positional arguments are forbidden (

param1) -

All arguments must be given the default value

None(param2). The reason for this is that we want, when the building block is called, all arguments to be passed explicitly, not implicitly.

-

3.2.4. Using default argument values in a building block

| we strongly discourage using this way of 'work around default parameters'. It is currently still implemented in the core system, but this behaviour might/will be removed in the future. |

In the code definition, it is not possible (prev. subsection).

It is nevertheless possible via an input file. The input file must

-

be in YAML format

-

bear the same name as the building block it corresponds to

-

be put in directory camtest/commanding/input

Example: building block camtest/commanding/hk_only.py

@building_block

def hk_only(wait_time=None):

time.sleep(wait_time)Corresponding input file camtest/commanding/input/hk_only.yaml

# 'hk_only' - Building Block

Args:

wait_time: 10 # System idle time [seconds]

3.2.5. Utility building blocks

A collection of low-level, general purpose building blocks is already provided in the commanding section of the plato-test-scripts (camtest/commanding), to help the test-developer, for instance to manipulate some hardware device, tune the OGSE light intensity, set the FEEs in different operating modes, acquire a number of full-frame images etc.

4. Test execution

4.1. Test execution: execute

The execution of a test is triggered by the Python function execute(). Like @building_block, it is a core functionality implemented by plato-test-scripts. It can be used with the following syntax:

>>> execute(building_block_name, param1=value1, param2=value2)All parameters must be specified by their name. No positional argument is allowed; hence the order of the parameters is not important. Note that the building block name does not have the paranthesis '()', only the name of the building block is given.

The execute command will start an observation and end the observation when the building block returns. Starting and ending an observation is an expensive operation in the sense that it notifies underlying mechanisms like the configuration and storage manager of the observation so they can take action. Therefore, although any building block can be executed using the execute(..) command, this should really only be used for higher level building blocks and from the Python prompt. Never use the execute(..) function inside a building block.

4.2. Preview the command sequence

| This functionality will be removed in the future as it has only limited applicability and doesn’t give a full consistent view of the command sequence. |

It is possible to perform a dry-run of a building-block by running generate_command_sequence() instead of execute(), with the same syntax. Be aware that the duration of the dry run may be as long as the execution itself!

>>> generate_command_sequence(building_block_name, param1=value1, param2=value2)This feature will execute all building blocks and functions without actually sending command strings to the test equipment. The current implementation does not take return values from device queries into account which makes it less suited for test scripts that need this feedback for conditional processing, e.g., waiting until a temperature is reached.

Note that execute and generate_command_sequence will only work under a set of restrictive conditions

-

Disposing of software simulators for every piece of equipment addressed by the test. Simulators exist in the EGSE for the N-FEEs and most of the equipment to be used in CSL.

-

Emulating an operational environment on your machine. We refer you to the EGSE documentation for the details of what this entails

4.3. Executing short building blocks individually

The execute command will trigger the creation of an obsid and an associated data stream. In the case were the operator (e.g. while setting up and testing the TH environment) want to execute short commands or building blocks outside of the scope of a test-script, this is an overkill and will make the analysis of the resulting data very cumbersome, because the data will be distributed over many very very short obsids.

To work around this, it is possible to manually start and stop an observation

>>> start_observation("Running a few examples")Will start an observation, attribute it an obsid and the associated data stream, just like what happens at the start of an execute.

After that any command passed (individually or within a function/building block) and any data generated will be recorded as part of the running obsid:

>>> command(args)

>>> func(args)

>>> building_block(args)Finally

>>> end_observation()Will close the observation (or do nothing if none is running).

5. Data acquisition and storage

All device housekeeping data and all camera telemetry data (image data and FEE HK) are automatically stored by the Storage Manager. You don’t need to collect and save data from within your scripts. Data is stored in a location on the egse-server and accessible from the desktop client machines running the tests and analysis scripts. This location is defined in the environment variable PLATO_DATA_STORAGE_LOCATION, which points to a /data directory.

Since release 2023.6.0+CGSE, the environment variable PLATO_DATA_STORAGE_LOCATION will not include the SITE ID anymore.

|

Several types of data are generated during a test campaign

-

Housekeeping telemetry (saved in CSV files)

-

From the test-item (e.g. TOU TRP-1 temperature)

-

From the test-environment (e.g. OGSE filter wheel position)

-

-

SpaceWire packets and register maps received from the FEE (saved in HDF5 files)

-

Image data from the camera (saved in FITS files)

-

Command history logging the test executions

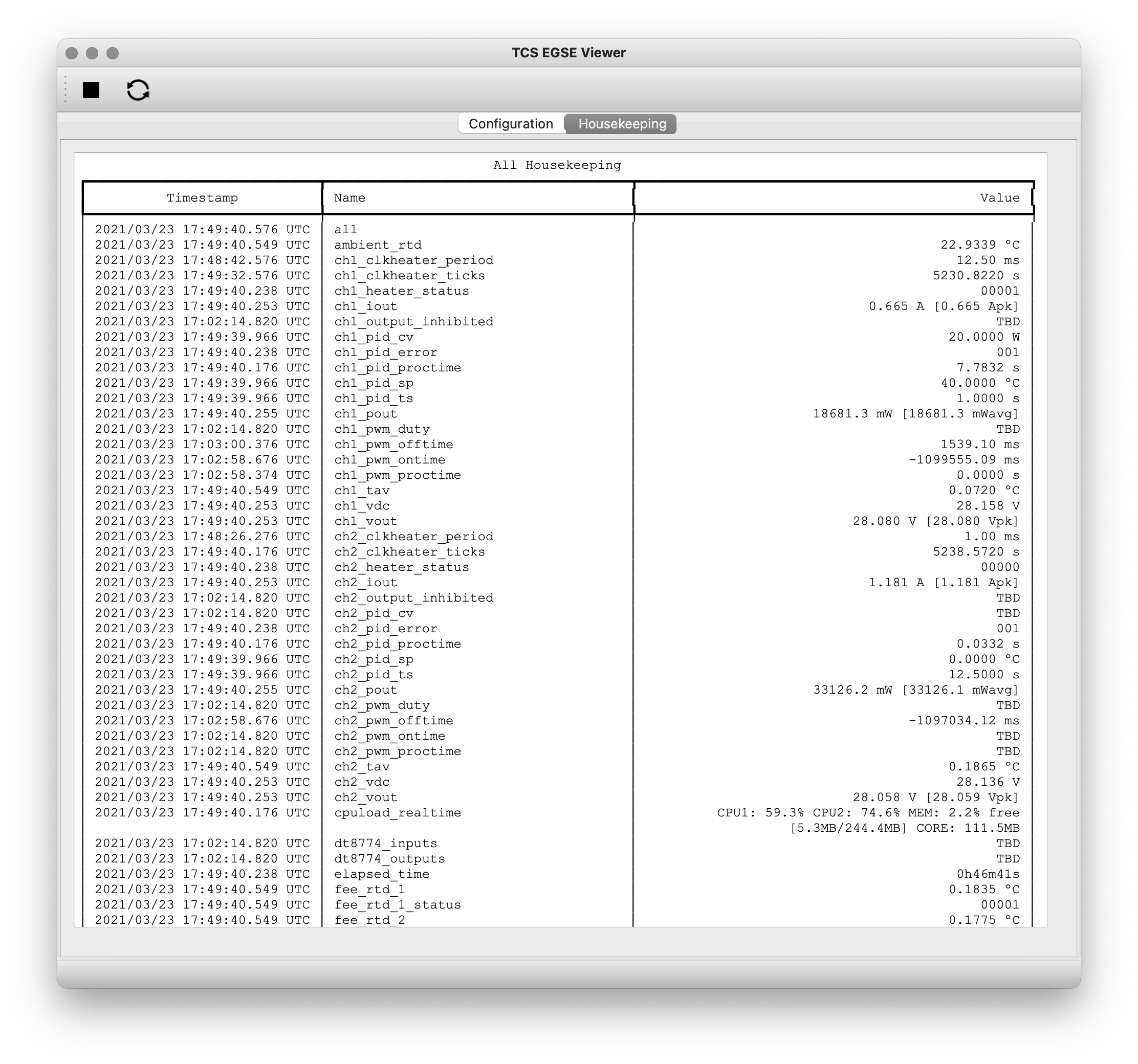

5.1. Housekeeping telemetry

The acquisition of housekeeping telemetry is automatically started by the egse-server. In practice that means that the telemetry from all devices connected to the active egse-server is automatically, and constantly recorded (see the Common-EGSE documentation for further details).

| Please note that all timestamps saved in housekeeping files are UTC. |

The housekeeping telemetry is structured this way

-

One file per day saved in a sub-folder of ‘daily’. The sub-folder is the

YYYYMMDDof that day. -

One CSV file per source of telemetry, i.e. for example one from the TCS, one for the hexapod (controller), one for the FEE etc.

-

Each CSV file contains a timestamp in the first columns, and the various entries in the subsequent columns.

-

All TM are recorded at 1Hz by default. This is configurable on a per-device-controller basis (= per CSV file)

The csv filenames have the following structure:

YYYYMMDD_SITE_DEVICE.csv

Where:

-

YYYYMMDDis the day the telemetry was taken -

SITEis the identifier for the test facility: CSL, IAS, INTA, SRON, KUL, ESA, … -

DEVICEis a mnemonic referring to the device controller issuing these data

For example, the daily file at CSL for the Hexapod PUNA housekeeping on June 8th, 2023 is 20230608_CSL_PUNA.csv. The header of the CSV files contains explicit column-names. The complete information on the content and format of the telemetry files is contained in the ICD (RD-04, see Reference Documents).

Excerpt of the PUNA hexapod telemetry file 20230608_CSL_PUNA.csv:

timestamp,GCSL1_HEX_USER_T_X,GCSL1_HEX_USER_T_Y,GCSL1_HEX_USER_T_Z,GCSL1_HEX_USER_R_X,GCSL1_HEX_USER_R_Y,GCSL1_HEX_USER_R_Z,GCSL1_HEX_MACH_T_X,GCSL1_HEX_MACH_T_Y,GCSL1_HEX_MACH_T_Z,GCSL1_HEX_MACH_R_X,GCSL1_HEX_MACH_R_Y,GCSL1_HEX_MACH_R_Z,GCSL1_HEX_ALEN_1,GCSL1_HEX_ALEN_2,GCSL1_HEX_ALEN_3,GCSL1_HEX_ALEN_4,GCSL1_HEX_ALEN_5,GCSL1_HEX_ALEN_6,GCSL1_HEX_HOMED,GCSL1_HEX_IN_POS

...

2023-06-08T10:00:01.560+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.1653351,205.52915657,205.97228441,205.88274269,206.14508725,True,True

2023-06-08T10:00:02.560+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.1653351,205.52915657,205.97228296,205.88274269,206.14508725,True,True

2023-06-08T10:00:03.563+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.1653351,205.52915657,205.97227986,205.88274269,206.14508725,True,True

2023-06-08T10:00:04.562+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.1653351,205.52915657,205.97227986,205.88274579,206.14508725,True,True

2023-06-08T10:00:05.562+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.1653351,205.52915657,205.97227986,205.88274269,206.14508725,True,True

2023-06-08T10:00:06.581+0000,0.014144539424,-0.003925761937,-3.489246984,-0.013989085157,0.0010419456108,-0.00799891817,0.390713812,0.1455886605,17.7970682,0.03226852454,0.06991046997,0.2646041152,205.93219583,206.16534276,205.52915967,205.97228296,205.88274579,206.14508725,True,True5.2. Observation

Image data are usually only generated during a test execution. In order to facilitate the selection of data pertaining to a particular test execution, we are using the concept of ‘observation’ interchangeably with the name “test”.

An observation corresponds to a single execution of a given test, i.e. a single use of the execute() command, or all commands executed between a start_observation and an end_observation.

A unique obsid is automatically attributed to every observation. The filenames of housekeeping files are constructed from the unique obsid and a limited set of useful metadata about the test execution, with the following structure:

TEST_SITE_SETUP_DEVICE_YYYYMMDD_HHMMSS.csv

where:

-

TESTis a unique test identifier, this is the first part of a full OBSID, -

SITEis the identifier for the test facility: CSL, IAS, INTA, SRON, KUL, ESA, … -

SETUPis the unique setup_id (section below) -

DEVICEis a mnemonic referring to the source of the data, e.g. the device controller issuing these data, the TCS EGSE, the N-FEE, etc. -

YYYYMMDD_HHMMSSpoints to the start of the test execution (UTC)

The first three items in the above list form the full OBSID. The OBSID can be abbreviated to the TEST-ID and the SITE-ID thereby omitting the SETUP-ID which can be automatically recovered from the meta data.

For instance, CSV files for observation 00757 performed at CSL could be:

-

00757_CSL_00009_PUNA_20201013_162037.csv -

00757_CSL_00009_CM_20201013_162037.csv

(PUNA points to a hexapod controller and CM refers to the Configuration Manager of the Common-EGSE).

For FITS files with the camera image data, the naming convention is similar (though we leave out the timestamp), with a sequencing number when the data volume justifies splitting of the data over multiple files.

-

00757_CSL_00009_N-FEE_CCD_00001_20201013_cube.fits -

00757_CSL_00009_N-FEE_CCD_00002_20201013_cube.fits

Note that we used to have two types of FITS files: FITS files in which the data is organised in a flat structure, and FITS files in which the data is organised in cubes (with filenames as described above). The former will have "image" in their names (rather than "cube") but will be removed once the corresponding cube-structure FITS file has been created.

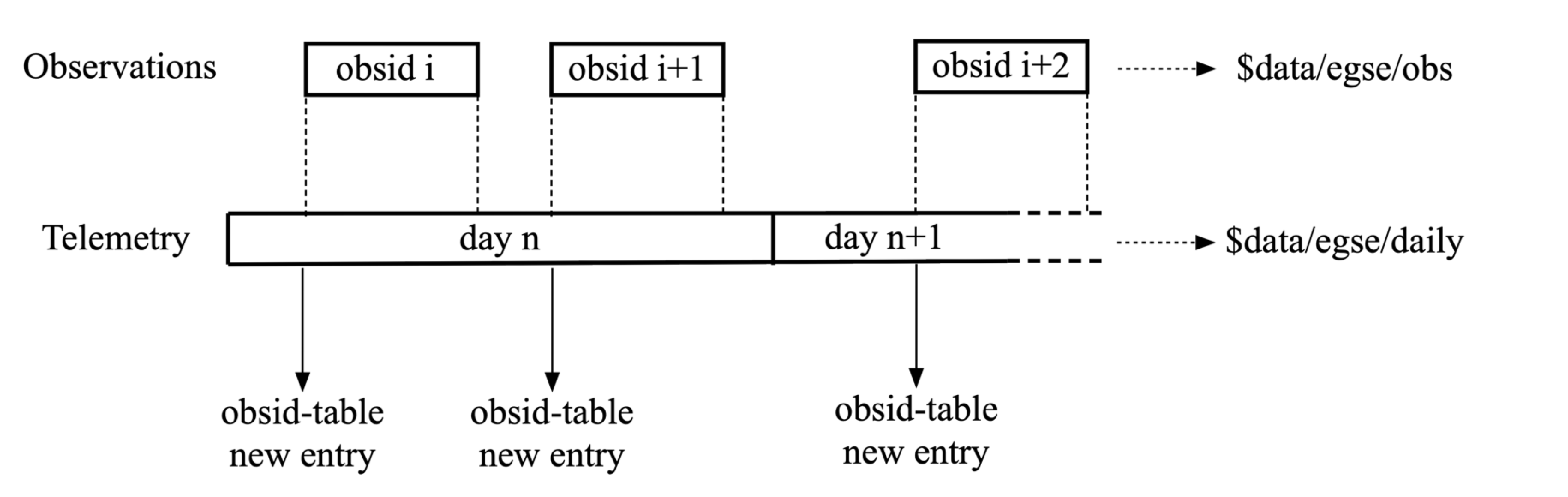

All data corresponding to the obsid are gathered in a dedicated directory named ‘obs’. That means that the fraction of the regular housekeeping data acquired during the execution of the observation is duplicated in that directory, keeping the same format as in the “daily” directory.

The data is hence stored in two different directories:

-

A “daily” directory, accumulating housekeeping telemetry data all day long (e.g. for trend analysis). Each day has its own sub-folder.

-

An “obs” directory, recording only observation-specific data and housekeeping in sub-folders containing the camera name also, e.g.

01061_CSL1_duvelis observation 1061 taken in clean room 1 at CSL for the FM#3, i.e. Duvel.

5.3. Image data

Image data are saved for each test execution as FITS files, with the corresponding housekeeping in csv files (see above).

Images are saved in FITS format, as UNSIGNED integers. You will have to cast them to float explicitly in python to avoid negative numbers to be wrongly interpreted.

Splitting: The DPU monitors a set of "crucial parameters" (see further) and each time at least one of these changes, a new FITS file will be created, provided the FEE is in full-image mode (or full-image pattern mode). Additionally, a maximum number of extensions is specified in the configuration (TBD). When that number is achieved, the image data are split, i.e. a new FITS file is opened to store the next block of image data.

Slicing: In a future version of the software, it will be possible to insert a given command in the test scripts in order to force the creation of a new FITS file. This will allow for a more flexible slicing of the data, i.e. enforce a clearer structure of the data, matching the commanding logic, and will facilitate the data analysis and interpretation.

Crucial parameters: As mentioned before, the DPU monitors (for changes in) crucial parameters. These are:

-

the first and last row that will be transmitted (

v_startandv_end), -

the last column that will be transmitted (

h_end), -

the number of rows that will be dumped after the requested number of rows have been transmitted (

rows_final_dump), -

the readout order of the CCDs (

ccd_readout_order), -

and the FEE mode (

ccd_mode_config), which should become/stay full-image mode or full-image pattern mode.

5.3.1. Data products

During the camera tests, the DPU will be configured such that a specific part of the E- and/or F-side of the selected CCDs will be transmitted (in the form of SpW packets) for a specified number of cycles (as explained in Section 12.4.2). The following information will be reconstructed from these SpW packets and stored in FITS files:

-

the transmitted image data from the selected side(s) of the selected CCDs, for all cycles,

-

the transmitted serial pre-scan data of the selected side(s) of the selected CCDs, for all cycles,

-

the transmitted serial over-scan data of the selected side(s) of the selected CCDs, for all cycles,

-

the transmitted parallel over-scan data of the selected side(s) of the selected CCDs, for all cycles.

While the SpW packets come in, the individual exposures are stored in individual extensions in FITS files that carry "images" in their name. This type of data arrangement is called a "flat structure". When there’s a change in crucial parameters, a new FITS file will be constructed (with "cube" in its name), based on the flat-structure FITS file, in which the exposures are aggregated into cubes. The original, flat-structure file will be removed from the system.

For analysis, only the FITS files with the cubes will be available, and therefore only the structure of these will be discussed in the section below.

In case both sides of a CCD are selected, the image data of both sides will be stitched together before storing it in the FITS file. This will also be done for the parallel over-scan data (if present). For the serial pre-scan and the serial over-scan, the information is stored per CCD side.

5.3.2. Internal structure

Each of the extensions (apart from the PRIMARY extension) will occur only once and comprise a 3D data array and a header with the metadata that is specific to that extension. The name of an extension will reflect what type of data product it comprises (e.g. image data of the F-side of CCD2, serial pre-scan data of the E-side of CCD3, etc.).

Although we have provided a set of convenience functions (see below) to extract information from a FITS file without being exposed to the internal details, we want to explain the internal structure in more detail.

The following extensions can be included in the FITS files:

| Extension name | Content |

|---|---|

PRIMARY |

Contains only header information, with metadata that pertains to the whole data product (site name, etc.). This extension always be present. |

SPRE_<1/2/3/4>_<E/F> |

Serial pre-scan data for the E-/F-side of CCD1/2/3/4. This extension will occur once (with all exposures included), if that side of that CCD was transmitted. |

SOVER_<1/2/3/4>_<E/F> |

Serial over-scan data for the E-/F-side of CCD1/2/3/4. I f this information is transmitted, this extension will occur once. |

POVER_<1/2/3/4>_<E/F> |

Parallel over-scan data for the E-/F-side of CCD1/2/3/4. If this information is transmitted, this extension will occur once. |

IMAGE_<1/2/3/4>_<E/F> |

Image data for the E-/F-side of CCD1/2/3/4. This extension will occur once (with all exposures included), if that-side of that CCD was transmitted. |

WCS-TAB_<1/2/3/4>_<E/F> |

Table with a single column (with the name TIME) in which the relative time (in seconds) w.r.t. the first exposure (of any CCD (side)) in the file is listed. |

Example 1: 4CCDs, full frame, 10 cycles

Relevant FEE parameters (see Section 12.4.2]):

-

ccd_readout = [1, 2, 3, 4];

-

ccd_side = BOTH;

-

num_cycles = 10;

-

row_start = 0;

-

row_end = 4510 + 30 - 1 (i.e. 4510 rows from the image + 30 rows from the parallel over-scan);

Structure/extensions of the FITS file:

-

PRIMARY: The primary extension (PrimaryHDU object). This does not contain any transmitted data. -

For CCD1:

-

1 extension

SPRE_1_E: The serial pre-scan for the E-side of CCD1 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SPRE_1_F: The serial pre-scan for the F-side of CCD1 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SOVER_1_E: The serial over-scan for the E-side of CCD1 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 in extension

SOVER_1_F: The serial over-scan for the F-side of CCD1 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 extension

POVER_1_E: The parallel over-scan for the E-side of CCD1 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

POVER_1_F: The parallel over-scan for the F-side of CCD1 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

IMAGE_1_E: The image data for the E-side of CCD1 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers -

1 extension

IMAGE_1_E: The image data of CCD1 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers

-

-

For CCD2:

-

1 extension

SPRE_2_E: The serial pre-scan for the E-side of CCD2 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SPRE_2_F: The serial pre-scan for the F-side of CCD2 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SOVER_2_E: The serial over-scan for the E-side of CCD2 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 in extension

SOVER_2_F: The serial over-scan for the F-side of CCD2 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 extension

POVER_2_E: The parallel over-scan for the E-side of CCD2 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

POVER_2_F: The parallel over-scan for the F-side of CCD2 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

IMAGE_2_E: The image data for the E-side of CCD2 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers -

1 extension

IMAGE_2_E: The image data of CCD2 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers

-

-

For CCD3:

-

1 extension

SPRE_3_E: The serial pre-scan for the E-side of CCD3 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SPRE_3_F: The serial pre-scan for the F-side of CCD3 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SOVER_3_E: The serial over-scan for the E-side of CCD3 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 in extension

SOVER_3_F: The serial over-scan for the F-side of CCD3 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 extension

POVER_3_E: The parallel over-scan for the E-side of CCD3 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

POVER_3_F: The parallel over-scan for the F-side of CCD3 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

IMAGE_3_E: The image data for the E-side of CCD3 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers -

1 extension

IMAGE_3_E: The image data of CCD3 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers

-

-

For CCD4:

-

1 extension

SPRE_4_E: The serial pre-scan for the E-side of CCD4 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SPRE_4_F: The serial pre-scan for the F-side of CCD4 (10 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 10 layers -

1 extension

SOVER_4_E: The serial over-scan for the E-side of CCD4 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 in extension

SOVER_4_F: The serial over-scan for the F-side of CCD4 (10 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 10 layers -

1 extension

POVER_4_E: The parallel over-scan for the E-side of CCD4 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

POVER_4_F: The parallel over-scan for the F-side of CCD4 (10 frames)

→ dimensions: 2255 columns x 30 rows x 10 layers -

1 extension

IMAGE_4_E: The image data for the E-side of CCD4 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers -

1 extension

IMAGE_4_E: The image data of CCD4 (10 frames)

→ dimensions: 2255 columns x 4510 rows x 10 layers

-

Example 2: E-side of CCD2, 100 lines in partial-readout mode, 25 cycles

Relevant FEE parameters (see Section 12.4.2]):

-

ccd_readout = [2, 2, 2, 2];

-

ccd_side = E;

-

num_cycles = 25;

-

row_end = row_start - 100 - 1

Note that this means that the E-side of CCD2 will be transmitted 4x25 times.

Structure/extensions of the FITS file:

-

PRIMARY: The primary extension (PrimaryHDU object). This does not contain any transmitted data. -

For CCD2:

-

1 extension

SPRE_2_E: The serial pre-scan for the E-side of CCD2 (4x25 frames)

→ dimensions: 25 columns x (4510 + 30) rows x 100 layers -

1 extension

SOVER_2_E: The serial over-scan for the E-side of CCD2 (4x25 frames)

→ dimensions: 15 columns x (4510 + 30) rows x 100 layers -

1 extension

POVER_2: The parallel over-scan for the E-side of CCD2 (4x25 frames)

→ dimensions: 4510 columns x 30 rows x 100 layers -

1 extension

IMAGE_2: The image data of CCD2 (4x25 frames)

→ dimensions: 4510 columns x 4510 rows x 100 layers

-

5.3.3. Inspecting the content

In the test scripts analysis package, i.e. the fitsfiles.py in camtest.analysis.functions, a number of convenience functions have been implemented to access information in the FITS files without detailed knowledge of the file structure. The remainder of this section will explain how to use these functions to access the different data parts in the FITS files.

5.3.3.1. Overview

The structure of the FITS files can be inspected with the following commands:

>>> get_overview(filename)

The output looks like to this (here only the E-side of CCD1 has been transmitted, without parallel over-scan):

No. Name Ver Type Cards Dimensions Format 0 PRIMARY 1 PrimaryHDU 5 () 1 SPRE_1_E 0 ImageHDU 12 (25, 100) float64 2 SOVER_1_E 0 ImageHDU 12 (15, 100) float64 3 IMAGE_1 0 ImageHDU 28 (2255, 100) float64 4 SPRE_1_E 0 ImageHDU 12 (25, 100) float64 5 SOVER_1_E 0 ImageHDU 12 (15, 100) float64 6 IMAGE_1 0 ImageHDU 28 (2255, 100) float64 7 SPRE_1_E 0 ImageHDU 12 (25, 100) float64 8 SOVER_1_E 0 ImageHDU 12 (15, 100) float64 9 IMAGE_1 0 ImageHDU 28 (2255, 100) float64 10 SPRE_1_E 0 ImageHDU 12 (25, 100) float64 11 SOVER_1_E 0 ImageHDU 12 (15, 100) float64 12 IMAGE_1 0 ImageHDU 28 (2255, 100) float64

Alternatively, you can get hold of a list with the extension names with

>>> get_ext_names(filename)

5.3.3.2. Primary header

The primary header can be retrieved as

>>> primary_header = get_primary_header(filename)

Note that all headers (for the primary header as well as for the other datasets) are returned as astropy.io.fits.header.Header objects. To get hold of the value of a specific header key, use:

>>> header[key]

The relevant keywords in the primary header are:

| Keyword | Description |

|---|---|

LEVEL |

This is present for historical reason and is fixed at 2, which indicates that it is a FITS file in which the data has been arranged into cubes. |

V_START |

The index of the first row that is transmitted. |

V_END |

The index of the last row that is transmitted. |

H_END |

The index of the last column that is transmitted. |

ROWS_FINAL_DUMP |

The number of rows that are dumped after the requested number of rows is transmitted. |

TELESCOP |

Set to "PLATO". |

INSTRUME |

The camera ID (as taken from the setup). |

SITENAME |

The name of the test site at which the data was acquired. |

SETUP |

The setup ID. |

CCD_READOUT_ORDER |

String representation of an array with the order inwhich the CCDs will be read out. |

CYCLETIME |

The image cycle time [s]. |

READTIME |

The time needed to read out the requested part for a single CCD side [s]. |

OBSID |

The observation identifier. |

DATE-OBS |

The timestamp of the first exposure (of any side of any CCD in the file). |

CGSE |

Version of the Common EGSE with which the FITS file was produced. |

5.3.3.3. Images

The image data of a specific exposure (counting starts at zero) of a specific side of a specific CCD can be retrieved as a numpy array, as follows:

>>> image_data = get_image_data(filename, ccd_number, ccd_side, exposure_number)

You can retrieve the image cubes and header for a specific side of a specific CCD as follows:

>>> image_cube_data = get_image_cube_data(filename, ccd_number, ccd_side) >>> image_cube_header = get_image_cube_header(filename, ccd_number, ccd_side)

The relevant keywords in the image header are:

| Keyword | Description |

|---|---|

NAXIS1 |

The number of columns in the image area of the CCD, that are transmitted (max 2255). |

NAXIS2 |

The number of rows in the image area of the CCD, that are transmitted (max 4510). |

NAXIS3 |

The number of exposures. |

FOCALLEN |

The focal length of the telescope [mm]. |

CTYPE1/CTYPE2 |

Set to "LINEAR" to indicate that a linear coordinate transformation is used (between pixels and mm), both in the column and row direction. |

CTYPE3 |

Set to "TIMETAB" to indicate that the 3rd axis will be characterised by tabulated (time) values. In the older FITS files, this was set to "TIME-TAB" (consistent with the Greisen & Calabretta papers), but the C code underlying astropy and the traditional FITS viewer need it to be "TIMETAB" instead. |

CUNIT1/CUNIT2 |

Set to "MM" to indicate that the focal-plane coordinates are expressed in mm, both in the column and row direction. |

CUNIT3 |

Set to "s" to indicate that the time is expressed in s. |

CDELT1/CDELT2 |

The pixels size [mm], both in the column and row direction. |

PS3_0 |

Set to "WCS-TAB_<1/2/3/4>_<E/F>" to indicate the the 3rd axis is characterised by the values in in the table, that is stored in a extension with that name. |

PS3_1 |

Set to "TIME" to indicate that the 3rd axis is characterised by the values in the table (see PS3_0) in the column with that name. |

SITENAME |

The name of the test site at which the data was acquired. |

EXTNAME |

The extension name, following the convention: IMAGE_<CCD number (1/2/3/4)>_<CCD side (E/F)> |

CCD_ID |

The CCD number (1/2/3/4). |

CROTA2 |

The orientation angle of the CCD [degrees]. This indicates over which angle the CCD reference frame is rotated w.r.t. the focal-plane reference plane, in counter-clockwise direction. |

CD1_1 |

The product of the pixel size and the cosine of the CCD orientation angle. |

CD1_2 |

The negative product of the pixel size and the sine of the CCD orientation angle. |

CD2_1 |

The product of the pixel size and the sine of the CCD orientation angle. |

CD2_2 |

The product of the pixel size and the cosine of the CCD orientation angle. |

CRVAL1 |

The focal-plane x-coordinate of the CCD origin [mm]. |

CRVAL2 |

The focal-plane y-coordinate of the CCD origin [mm]. |

CRPIX1 |

The column coordinate of the CCD origin w.r.t. the first transmitted column of the image area. |

CRPIX2 |

The row coordinate of the CCD origin w.r.t. the first transmitted row of the image area. |

OBSID |

The observation identifier. |

DATE-OBS |

The timestamp of the start of the data acquisition of the first exposure. |

5.3.3.4. Parallel over-scan

To get hold of the data (as a numpy array) of a parallel over-scan (if present) for a specific exposure (counting starts at 0) of a specific side of a specific CCD, execute the following command:

>>> parallel_overscan_data = get_parallel_overscan_data(filename, ccd_number, ccd_SIDE, exposure_number)

You can retrieve the parallel over-scan data and header for a specific side of a specific CCD as follows:

>>> parallel_overscan_cube_data = get_ parallel_overscan_cube_data(filename, ccd_number, ccd_side) >>> parallel_overscan _cube_header = get_ parallel_overscan_cube_header(filename, ccd_number, ccd_side)

The relevant keywords in the parallel over-scan header are:

| Keyword | Description |

|---|---|

NAXIS1 |

The number of columns in the parallel over-scan, that are transmitted. |

NAXIS2 |

The number of rows in the parallel over-scan of the CCD, that are transmitted. |

NAXIS3 |

The number of exposures. |

CTYPE3 |

Set to "TIMETAB" to indicate that the 3rd axis will be characterised by tabulated (time) values. In the older FITS files, this was set to "TIME-TAB" (consistent with the Greisen & Calabretta papers), but the C code underlying astropy and the traditional FITS viewer need it to be "TIMETAB" instead. |

CUNIT3 |

Set to "s" to indicate that the time is expressed in s. |

PS3_0 |

Set to "WCS-TAB_<1/2/3/4>_<E/F>" to indicate the the 3rd axis is characterised by the values in in the table, that is stored in a extension with that name. |

PS3_1 |

Set to "TIME" to indicate that the 3rd axis is characterised by the values in the table (see PS3_0) in the column with that name. |

FOCALLEN |

The focal length of the telescope [mm]. |

SITENAME |

The name of the test site at which the data was acquired. |

EXTNAME |

The extension name, following the convention: IMAGE_<CCD number (1/2/3/4)>_<CCD side (E/F)> |

CCD_ID |

The CCD number (1/2/3/4). |

OBSID |

The observation identifier. |

DATE-OBS |

The timestamp of the start of the data acquisition of the first exposure. |

5.3.3.5. Serial pre-scan

To get hold of the data (as a numpy array) of a serial pre-scan for a specific exposure (counting starts at 0) of a specific side of a specific CCD, execute the following command:

>>> serial_prescan_data = get_serial_prescan_data(filename, ccd_number, ccd_side, exposure_number)

You can retrieve the serial pre-scan data and header for a specific side of a specific CCD as follows:

>>> serial_prescan_cube_data = get_ serial_prescan _cube_data(filename, ccd_number, ccd_side) >>> serial_prescan _cube_header = get_ serial_prescan_cube_header(filename, ccd_number, ccd_side)

The relevant keywords in the serial pre-scan header are:

| Keyword | Description |

|---|---|

NAXIS1 |

The number of columns in the serial pre-scan (fixed at 25). |

NAXIS2 |

The number of rows in the serial pre-scan, that are transmitted. |

NAXIS3 |

The number of exposures. |

CTYPE3 |

Set to "TIMETAB" to indicate that the 3rd axis will be characterised by tabulated (time) values. In the older FITS files, this was set to "TIME-TAB" (consistent with the Greisen & Calabretta papers), but the C code underlying astropy and the traditional FITS viewer need it to be "TIMETAB" instead. |

CUNIT3 |

Set to "s" to indicate that the time is expressed in s. |

PS3_0 |

Set to "WCS-TAB_<1/2/3/4>_<E/F>" to indicate the the 3rd axis is characterised by the values in in the table, that is stored in a extension with that name. |

PS3_1 |

Set to "TIME" to indicate that the 3rd axis is characterised by the values in the table (see PS3_0) in the column with that name. |

SITENAME |

The name of the test site at which the data was acquired. |

EXTNAME |

The extension name, following the convention: SPRE_<CCD number (1/2/3/4)>_<CCD side (E/F)> |

CCD_ID |

The CCD number (1/2/3/4). |

OBSID |

The observation identifier. |

DATE-OBS |

The timestamp of the start of the data acquisition of the first exposure. |

5.3.3.6. Serial over-scan

To get hold of the data (as a numpy array) of a serial over-scan for a specific exposure (counting starts at 0) of a specific side of a specific CCD, execute the following command

>>> serial_overscan_data = get_serial_overscan_data(filename, ccd_number, ccd_side, exposure_number)

You can retrieve the serial over-scan data and header for a specific side of a specific CCD as follows:

>>> serial_overscan_cube_data = get_ serial_overscan_cube_data(filename, ccd_number, ccd_side) >>> serial_overscan _cube_header = get_ serial_overscan_cube_header(filename, ccd_number, ccd_side)

The relevant keywords in the serial over-scan header are:

| Keyword | Description |

|---|---|

NAXIS1 |

The number of columns in the serial over-scan. |

NAXIS2 |

The number of rows in the serial over-scan, that are transmitted. |

NAXIS3 |

The number of exposures. |

CTYPE3 |

Set to "TIMETAB" to indicate that the 3rd axis will be characterised by tabulated (time) values. In the older FITS files, this was set to "TIME-TAB" (consistent with the Greisen & Calabretta papers), but the C code underlying astropy and the traditional FITS viewer need it to be "TIMETAB" instead. |

CUNIT3 |

Set to "s" to indicate that the time is expressed in s. |

PS3_0 |

Set to "WCS-TAB_<1/2/3/4>_<E/F>" to indicate the the 3rd axis is characterised by the values in in the table, that is stored in an extension with that name. |

PS3_1 |

Set to "TIME" to indicate that the 3rd axis is characterised by the values in the table (see PS3_0) in the column with that name. |

SITENAME |

The name of the test site at which the data was acquired. |

EXTNAME |

The extension name, following the convention: SOVER_<CCD number (1/2/3/4)>_<CCD side (E/F)> |

CCD_ID |

The CCD number (1/2/3/4). |

OBSID |

The observation identifier. |

DATE-OBS |

The timestamp of the start of the data acquisition of the first exposure. |

5.3.3.7. Time

To get hold of the relative time (as a numpy array) in seconds w.r.t. the first exposure (of any side of any CCD in the file) for the exposures for a specific side of a specific CCD, execute the following command:

>>> from camtest.analysis.functions.fitsfiles import get_relative_time >>> relative_time = get_relative_time(filename, ccd_number, ccd_side) >>> relative_time = get_relative_time(hdu_list_object, ccd_number, ccd_side)

The absolute time (as a numpy array) in seconds since epoch 1958, for the exposures for a specific side of a specific CCD, can be retrieved as follows:

>>> from camtest.analysis.functions.fitsfiles import get_absolute_time >>> absolute_time = get_absolute_time(filename, ccd_number, ccd_side) >>> absolute_time = get_absolute_time(hdu_list_object, ccd_number, ccd_side)

5.3.3.8. Focal-plane coordinates

To convert image pixel coordinates (row, column) for a given side of a given CCD to focal-plane coorinates (x, y), in mm, execute:

>>> from camtest.analysis.functions.fitsfiles import get_fp_coordinates >>> x, y = get_fp_coordinates(filename, ccd_number, ccd_side, row, column) >>> x, y = get_fp_coordinates(hdu_list_object, ccd_number, ccd_side, row, column)

5.3.3.9. Astropy WCS objects

It is possible to load the headers into an astropy WCS object, which can be used for coordinate conversions:

>>> from astropy.io import fits >>> from astropy.wcs import WCS >>> with fits.open(<filename>) as hdul: ... header = hdul[<extension name>].header >>> wcs = WCS(header)

For the older FITS files, you may get this error message (see #1714):

ERROR: ValueError: ERROR 5 in wcsset() at line 2352 of file cextern/wcslib/C/wcs.c: Invalid parameter value. ERROR 3 in tabset() at line 747 of file cextern/wcslib/C/tab.c: Invalid tabular parameters: Each element of K must be positive, got 0.

This can be circumvented by correcting the value for the CTYPE3 keyword (before creating the WCS object):

>>> header["CTYPE3"] = "TIMETAB"

5.4. Telecommand history

The complete telecommand history is not yet saved but can be reconstructed from the setup_id (see below) and the obsid-table. The obsid-table.txt is a text file located at the root of the data storage location. The file contains one entry per observation, associating

-

the main parameters of the observation, obsid and site

-

the time of execution

-

the setup_id active at execution time (contains the version number of the plato-test-script on the operational server)

-

The building block name

-

All parameter names and values passed to the execute command

The following lines are examples taken from the obsid-table.txt file at CSL:

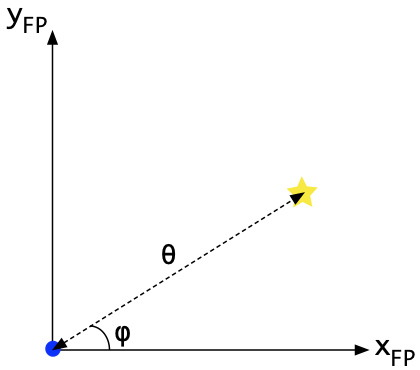

01108 CSL1 00084 2023-06-07T08:56:22.832+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01109 CSL1 00084 2023-06-07T08:57:30.003+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01110 CSL1 00084 2023-06-07T09:02:16.140+0000 check_and_move_relative_user(cslmodel="egse.coordinates.cslmodel.CSLReferenceFrameModel", translation="[0, 0, 0.01]", rotation="[0, 0, 0]", setup="egse.setup.Setup", verbose="True")

01111 CSL1 00084 2023-06-07T09:03:09.426+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01112 CSL1 00084 2023-06-07T09:06:40.668+0000 check_and_move_relative_user(cslmodel="egse.coordinates.cslmodel.CSLReferenceFrameModel", translation="[0, 0, 0.005]", rotation="[0, 0, 0]", setup="egse.setup.Setup", verbose="True")

01113 CSL1 00084 2023-06-07T09:08:28.446+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01114 CSL1 00084 2023-06-07T09:29:58.225+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01115 CSL1 00084 2023-06-07T09:37:08.043+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")

01116 CSL1 00084 2023-06-07T09:40:39.185+0000 cam_single_cube_int_sync(theta="8.3", phi="12.0", num_cycles="5", exposure_time="0.2", n_rows="1000", attenuation="0.00413")The obsid-table.txt file is explained in more detail in the Interface Control Document (ICD) [RD-04].

6. Configuration and Setups

The complete documentation on the EGSE configuration and on the concept of Setup can be found in the developer manual.

Setup is the concept we attach to the entity encapsulating the entire set of

-

identifiers and configuration items,

-

calibration values and calibration files,

necessary to

-

describe the test-environment and the item under test, and to

-

operate the test.

6.1. Example Setup file

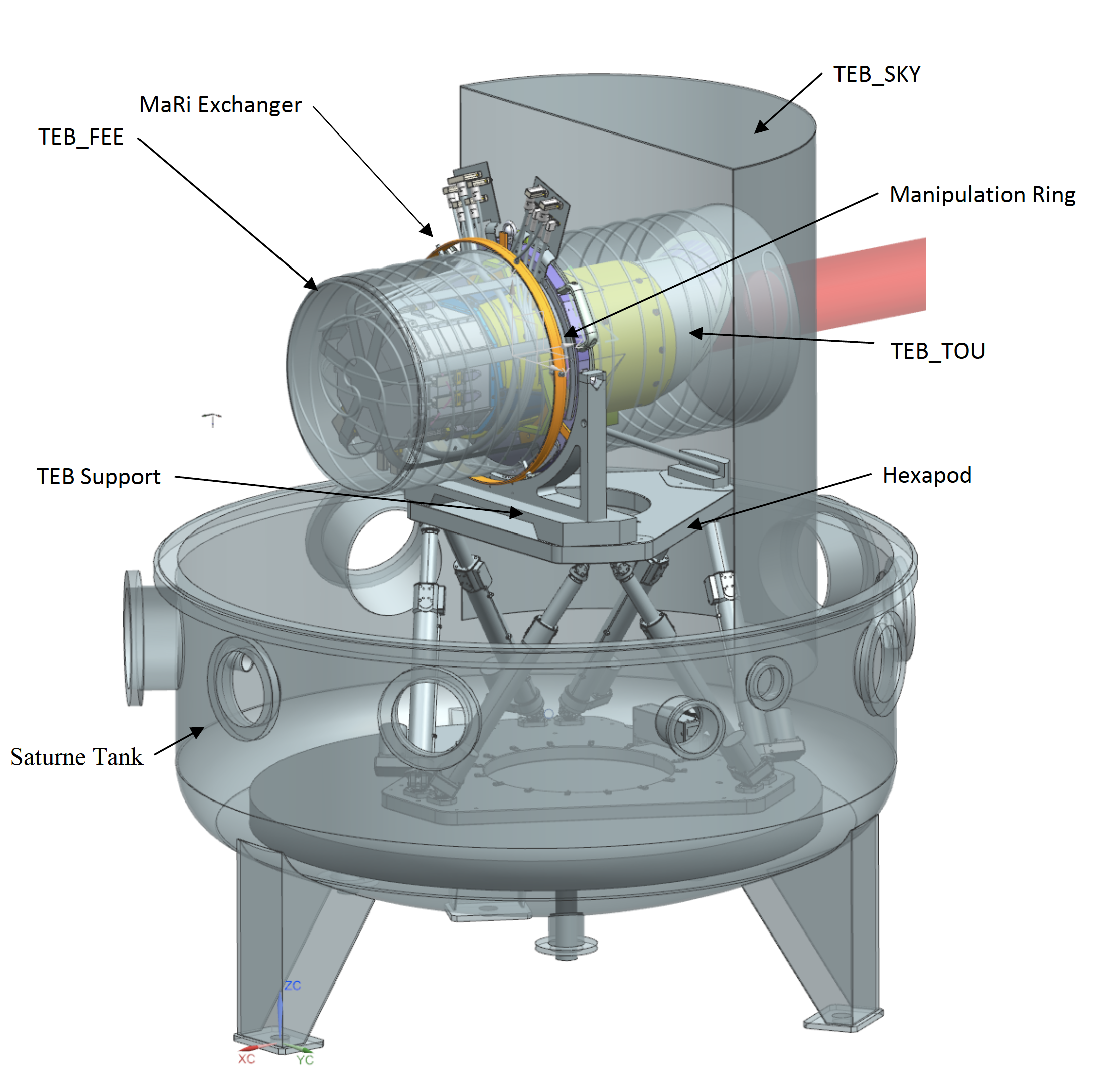

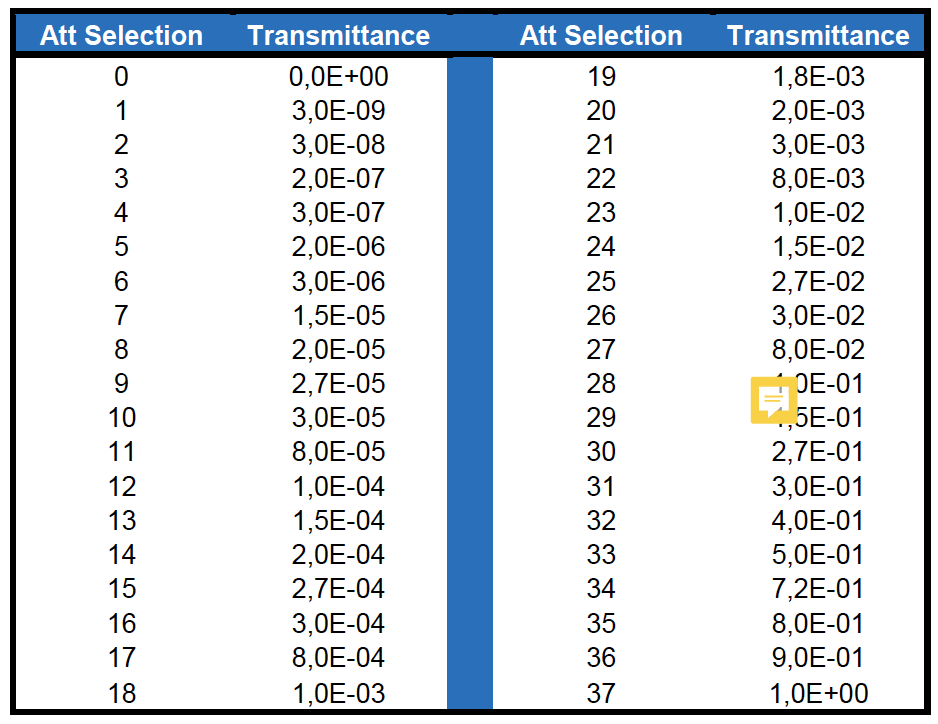

A snippet of a setup file is shown below. It shows the tree structure of the YAML file. At the top level are the main components: gse (devices), camera (fpa, tou, fee), telemetry, etc. The snippet only shows part of the Setup. Under the gse branch we have hexapod and stages and many more that are not shown. All ground equipment that is part of the test setup shall have an entry under the gse branch. The information that shall go into these entries is device identification, calibration information, specific device settings, etc.

Everything that is connected to the Camera, i.e. SUT, shall go under the camera branch. This is e.g. identifiers for the TOU, FEE, FPA, DPU, CCD, …, calibration information, defaults, numbering, avoidance information, etc.

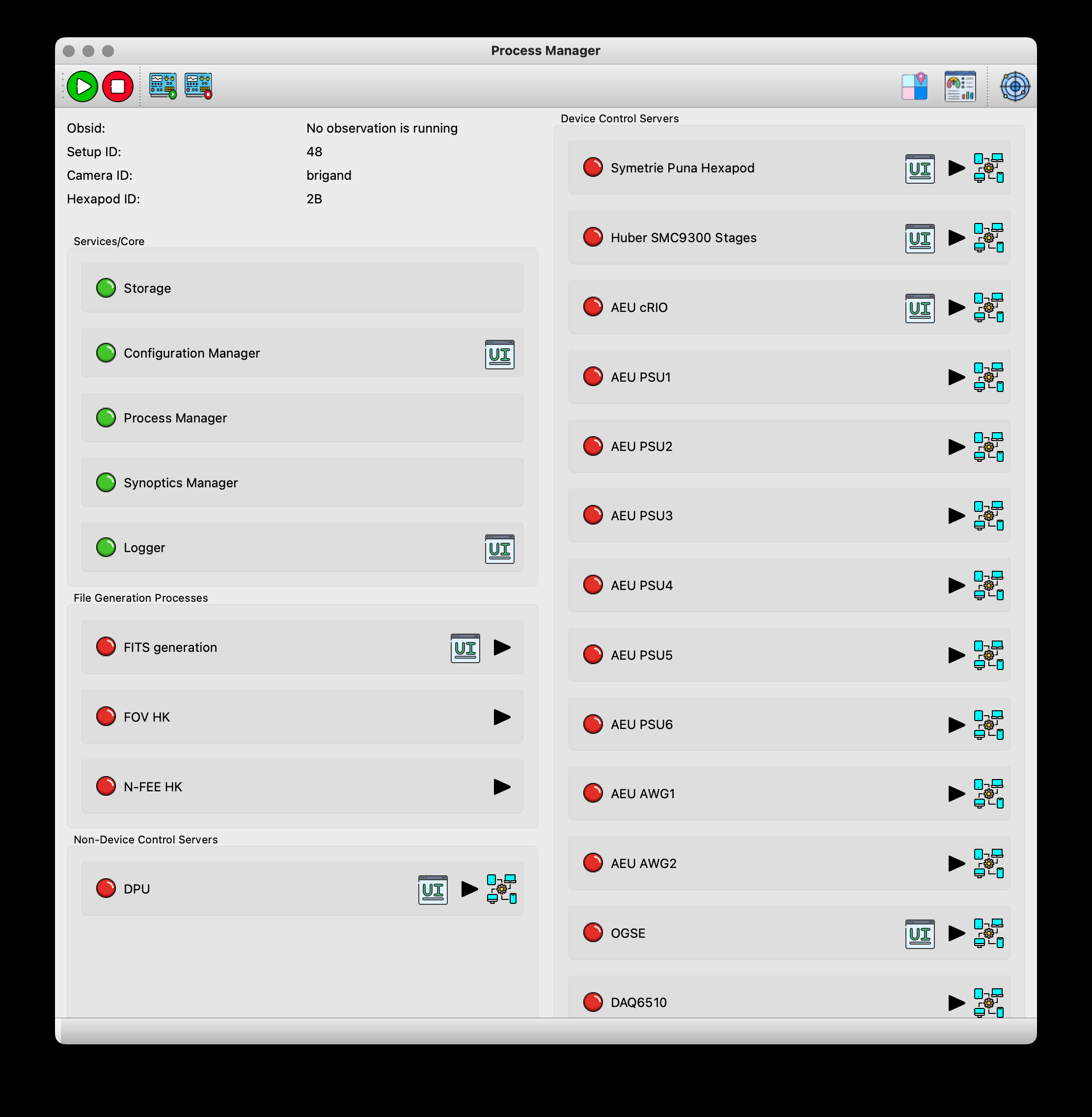

| The gse branch is also used by the process manager to determine which devices are part of the Setup and for which devices it should present a status LED and a start/stop button. |

The users are allowed to modify or add items and branches to the setup and save a new version of it. As an example, the stages branch in this example contains calibration values defining metrology of the rotation and translation stages used to position the light beam at CSL.

NavigableDict ├── site_id: CSL2 ├── position: 2 ├── gse │ ├── hexapod │ │ ├── device: class//egse.hexapod.symetrie.puna.PunaProxy │ │ ├── device_name: Symetrie Puna Hexapod │ │ ├── ID: 2B │ │ ├── time_request_granularity: 0.1 │ │ ├── CID: 603382 │ │ └── label: 172543 - PUNA │ ├── stages │ │ ├── ID: 1 │ │ ├── BIG_ROTATION_STAGE_ID: 420-20913 │ │ ├── SMALL_ROTATION_STAGE_ID: 409-10661 │ │ ├── TRANSLATION_STAGE_ID: 5101.30-943 │ │ ├── device: class//egse.stages.huber.smc9300.HuberSMC9300Proxy │ │ ├── device_name: Huber SMC9300 Stages │ │ ├── calibration │ │ │ ├── height_collimated_beam: 513.9 │ │ │ ├── offset_phi: 0.4965 │ │ │ ├── offset_alpha: 0.0 │ │ │ ├── offset_delta_x: 96.884 │ │ │ ├── phi_correction_coefficients: [-0.0049, 0.0003] │ │ │ ├── alpha_correction_coefficients: [0.0856, -0.5] │ │ │ └── delta_x_correction_coefficients: [-0.1078, 0.2674, -0.0059] │ │ ├── big_rotation_stage │ │ │ ├── avoidance: 3.0 │ │ │ ├── hardstop: 179.316 │ │ │ └── default_speed: 15000 │ │ ├── small_rotation_stage │ │ │ └── default_speed: 15000 │ │ └── translation_stage │ │ └── default_speed: 15000 ... ├── camera │ ├── TOU │ │ └── ID: BA-N1-11130000-FM-01 │ ├── fpa │ │ ├── avoidance │ │ │ ├── clearance_xy: 2.0 │ │ │ ├── clearance_z: 2.0 │ │ │ ├── vertices_nb: 60 │ │ │ └── vertices_radius: 100.0 │ │ ├── ID: N-FPA-11200000-FM-01 │ │ └── max_offset: 20 │ ├── dpu │ │ ├── device: class//egse.dpu.DPUProxy │ │ └── device_name: DPU ... ├── telemetry │ ├── dictionary: pandas//../../common/telemetry/tm-dictionary-brigand.csv │ └── separator: ; ├── sensor_calibration │ └── callendar_van_dusen │ └── EN60751 │ ├── A: 0.0039083 │ ├── B: -5.775e-07 │ └── C: -4.183e-12 ├── history │ ├── 0: Initial zero Setup for CSL2 │ ├── 1: Copy of CSL setup 97 (last EM setup) │ ├── 2: Removed TCS block

You can check the version of the Setup with the following command:

>>> print(setup.get_id()) 00068

The number printed on your system will be different.

6.2. Available Setups

Setups will be available in the form of YAML files that are stored in the plato-cgse-conf repository and are located (probably) at ~/git where the repos are kept.

| Do never edit these YAML files directly since they are maintained through changes on the operational machine. The configuration manager on the egse-server machine manages these Setups and brings them under configuration control in GitHub automatically upon submitting a new Setup. |

Browsing through the available setups can either be done in Python or via a GUI.

6.2.1. Browsing the Setups in Python

To get a list of the setups that are available in the system, execute the following command (to be imported from camtest):

>>> list_setups()

This will return a list of (setup identifier, site identifier) pairs, e.g.

('00037', 'CSL2', 'Use v2 of N-FEE sensor calibration for Chimay (#293)', 'brigand')

('00038', 'CSL2', 'Incl. nominal ranges for power consumption checks (#312)', 'brigand')

('00039', 'CSL2', 'Updated N-cam voltages for the AEU PSU (#315)', 'brigand')

('00040', 'CSL2', 'New CSLReferenceFrameModel [csl_model_from_file]', 'brigand')

('00041', 'CSL2', 'Putting back N-cam voltages for the AEU PSU', 'brigand')

('00042', 'CSL2', 'updated stages calibration (beam height and phi correction)', 'brigand')

('00043', 'CSL2', 'Updated AEU voltages + voltage/current protection values (#324)', 'brigand')

('00044', 'CSL2', 'updated translation stage zero position', 'brigand')

('00045', 'CSL2', 'Update AEU configuration according to - NRB NCR-CSL-0036 disposition, email by Yves on 24/05/2023', 'brigand')The list_setups() command also allows you to filter the results, by using any of the keywords inside the setups. For instance, to list all the setups related to the STM version of the TOU, tested with the hexapod No 1 at CSL, you would type

>>> list_setups(camera__ID="achel") (1)

| 1 | Note that the double underscore “__” is used to navigate the Setup. All parameters passed will be joined with a logical AND. |

list_setups(camera__ID="achel")

('00004', 'CSL2', 'Copy camera and telemetry info for achel from CSL1 setup 38', 'achel')

('00005', 'CSL2', 'Incl. sensor calibration', 'achel')

('00006', 'CSL2', 'Updated hexapod ID', 'achel')

('00007', 'CSL2', 'Updated device name for DAQ6510 (#235)', 'achel')

('00008', 'CSL2', 'Using short sync pulses of 200ms (instead of 150ms)', 'achel')

('00009', 'CSL2', 'Copy camera and telemetry info for achel from CSL1 setup 45', 'achel')

('00010', 'CSL2', 'Incl. MGSE calibration coefficients (#255)', 'achel')

('00011', 'CSL2', 'New CSLReferenceFrameModel [csl_model_from_file]', 'achel')

('00012', 'CSL2', 'Changed offset_phi for validation purposes', 'achel')

('00013', 'CSL2', 'Recalibration of the SMA (#258)', 'achel')

('00014', 'CSL2', 'Updated reference Hartmann positions (#254)', 'achel')

('00015', 'CSL2', 'fixed alpha correction coefficients', 'achel')

('00016', 'CSL2', 'Incl. reference_full_76 (taken from CSL1 setup 46)', 'achel')

('00017', 'CSL2', 'New CSLReferenceFrameModel [csl_model_from_file]', 'achel')

('00018', 'CSL2', 'Copy camera and telemetry info for achel from CSL1 setup 47', 'achel')

('00019', 'CSL2', 'Updated x, y measured positions w.r.t. LDO input (#266)', 'achel')

6.2.2. Using the Setup GUI

To open the GUI to inspect all available setups, type the following command:

$ setup_ui

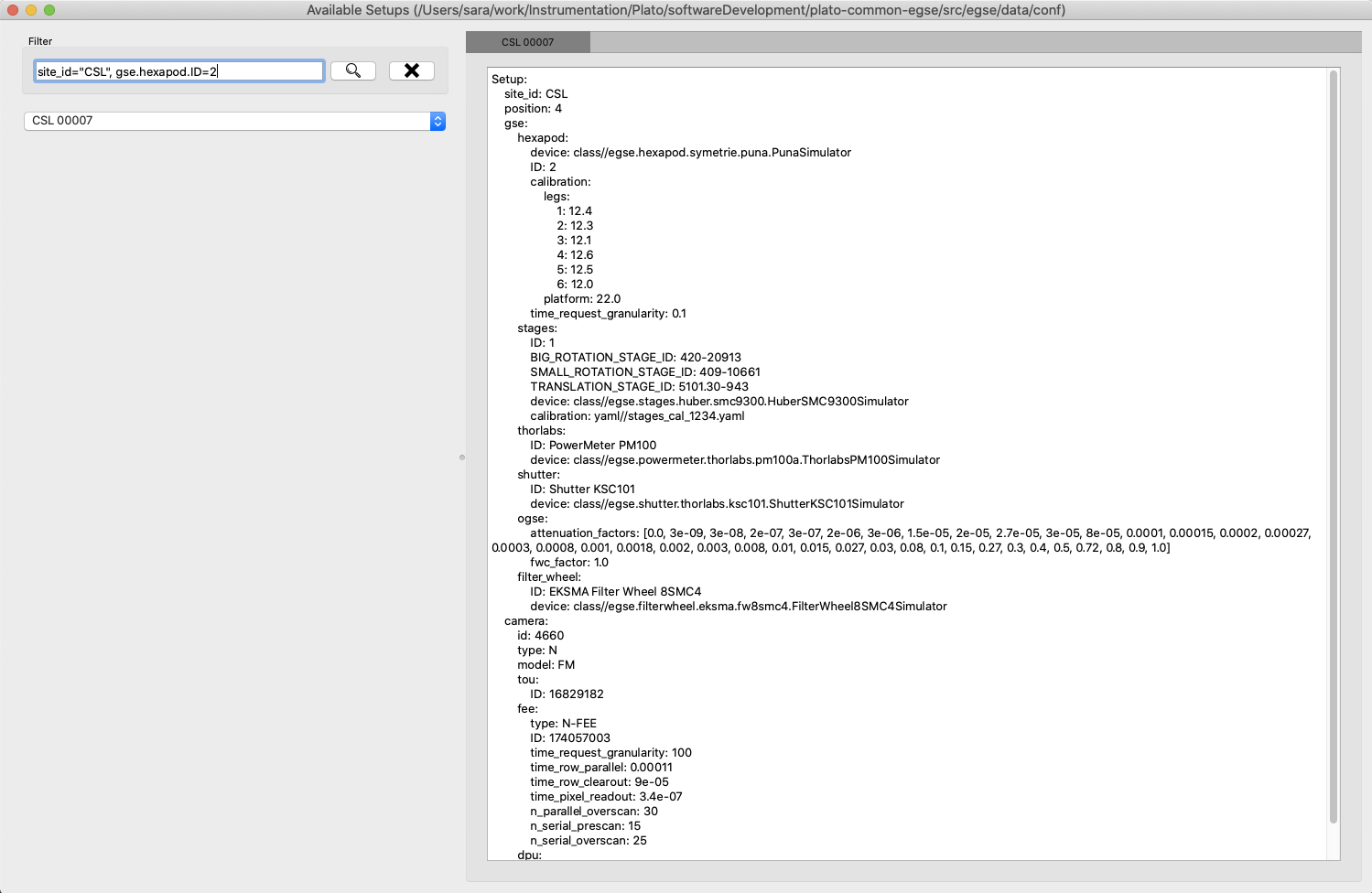

This will fire up a window as shown in Figure 3. The directory that is mentioned in the window title, is the one where the available setups are located.

A text field on the left-hand side allows you to filter the setups, similar to the arguments of the list_setups command from Section 6.2.1. You can navigate through the tree both with the '__' and the dot notation. For the available setups that pass the filtering, the site and setup identifier will appear in the drop-down menu, after either hitting the return key in the filter text field or by pressing the search button next to it.

6.3. Loading a Setup

After inspection of the available setups, a specific setup can be loaded, based on the identifier.

| Loading a Setup means to load it in the system such that it then becomes the reference for the system configuration. This means it impacts the GlobalState and the ConfigurationManager! It is different from getting a copy of a Setup as a variable in a python script (see below). |

Ideally, the Setup will be loaded one single time at the start of a test phase, with a setup reflecting the HW present in the test environment. The preferred way to do so is via the setup GUI. That can be launched via

$ setup_ui

In python:

>>> from camtest import load_setup >>> setup = load_setup(7)

The above command will load the Setup in the configuration manager and also in the Python console you used to execute the load_setup() command.

| Loading or submitting a Setup will have an effect on the configuration manager. The Setup is however NOT automatically propagated to all components in the system like e.g the device drivers. Therefore, always check if you have the right Setup available, especially in the QtConsole. The Setup is however propagated to all the core services, sm_cs, pm_cs (TODO), syn_cs. |

You can check which Setup is loaded in the core services using the status parameter:

$ cm_cs status Configuration manager: Status: active Site ID: CSL2 No observation running Setup loaded: 00068 Hostname: 192.168.0.163 Monitoring port: 6001 Commanding port: 6000 Service port: 6002 Listeners: Storage CS

Also the process manager (pm_ui) and the Operator GUI (e.g. csl_ui) indicate which Setup is loaded, but keep in mind that this is only true for that particular process and is not necessarily propagated to all processes running in this distributed environment.

6.4. Inspecting, accessing, and modifying a Setup

First, make sure a Setup is already loaded in the system, and that you have a variable attached to a setup in your Python session. Here we call it setup.

You can get a Setup with the following command

>>> from camtest import get_setup >>> setup = get_setup(7)

This will read the content of Setup "00007" for the site you are currently at and assign it to a variable called setup.

| This has no effect on the system configuration (the ConfigurationManager will not know about it, and the GlobalState won’t be affected). |

6.4.1. Content of the setup

To print the entire content of the setup:

>>> print(setup)

The Setups, as well as all of their branches are “navigable dictionaries”. In practice that means that they have a tree structure, and every part of the tree can be accessed with a simple syntax, using dot notation (in contrast to using a double underscore (__) when filtering the available Setups).

6.4.2. Inspect a given branch or leaf

You can inspect any branch or leaf of the Setup by navigating the Setup and printing the result:

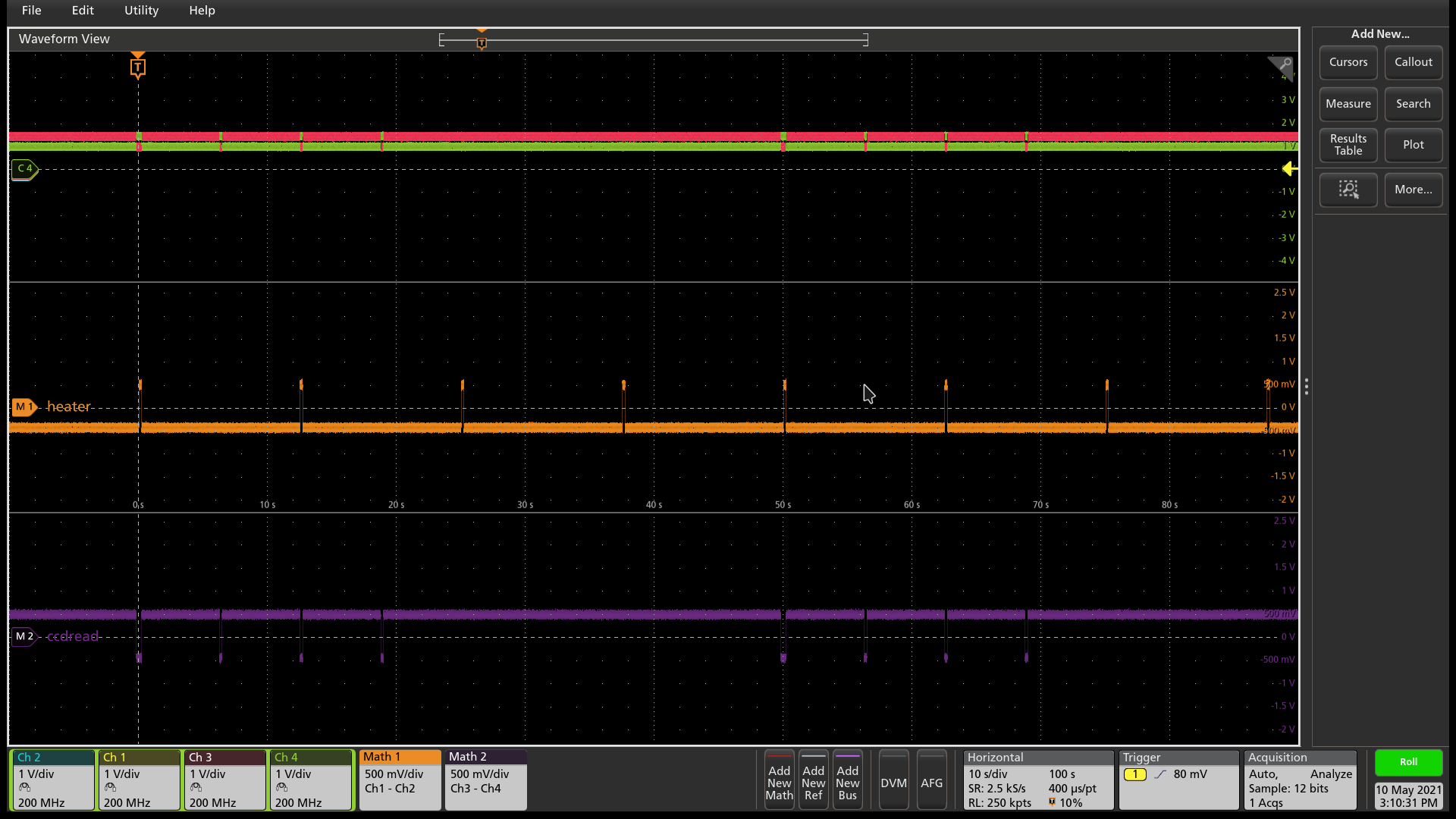

>>> print(setup.branch.subbranch.leaf)